In the competitive world of packaging, maintaining high standards of quality and efficiency is crucial. The SeamCheck Plus automatic double seam projector is a cutting-edge solution designed to elevate these standards. This article delves into how the SeamCheck Plus enhances packaging quality and efficiency, making it an indispensable tool in the packaging industry.

Quality packaging is vital for product safety and brand reputation. The SeamCheck Plus ensures that every package meets the highest standards through precise double seam inspection. This technology not only improves packaging quality but also boosts overall efficiency, reducing waste and ensuring consistency. By understanding the benefits and features of the SeamCheck Plus, businesses can make informed decisions to optimize their packaging processes.

Table of Contents

Introduction to SeamCheck Plus

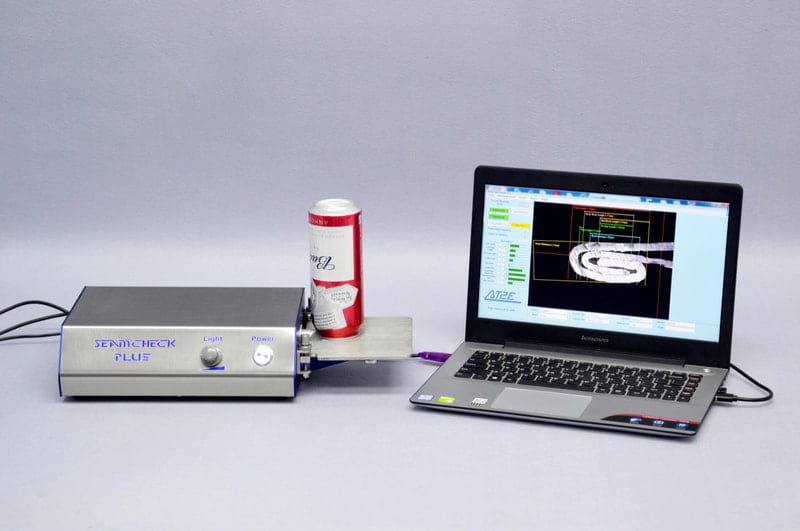

The SeamCheck Plus is an advanced tool designed for automatic double seam inspection. It utilizes state-of-the-art technology to provide precise measurements and detailed analysis of packaging seams. This device is essential for ensuring the integrity and quality of various types of packaging, particularly in industries where packaging plays a critical role in product safety and shelf life.

High-Resolution Imaging

One of the standout features of the SeamCheck Plus is its high-resolution imaging capability. This allows for detailed examination of the double seam, identifying any potential issues that could compromise the packaging’s integrity.

Automatic Measurement

The SeamCheck Plus automates the measurement process, significantly reducing the time required for inspection. This automation not only enhances efficiency but also ensures consistent accuracy in seam measurement.

User-Friendly Interface

The SeamCheck Plus is designed with a user-friendly interface, making it easy for operators to perform inspections and interpret results. The intuitive design ensures that even users with minimal technical expertise can effectively use the device.

Enhancing Packaging Quality

Accurate Double Seam Inspection

Accurate double seam inspection is critical for maintaining packaging quality. The SeamCheck Plus excels in this area by providing precise measurements and detailed analysis of the seam. This accuracy helps in identifying any discrepancies that could affect the packaging’s performance.

Consistency in Packaging

Consistency is key to quality packaging. The SeamCheck Plus ensures that every package meets the same high standards, reducing variability and improving overall quality. This consistency is crucial for maintaining brand reputation and customer satisfaction.

Reduction in Defects

By accurately inspecting double seams and identifying potential issues early, the SeamCheck Plus helps reduce defects. This proactive approach minimizes waste and prevents defective products from reaching consumers, enhancing overall quality control.

Boosting Packaging Efficiency

Faster Inspection Times

The automation features of the SeamCheck Plus lead to faster inspection times. This efficiency is crucial in high-volume production environments where time is of the essence. Faster inspections mean quicker turnaround times and increased productivity.

Data Integration and Analysis

The SeamCheck Plus allows for seamless data integration and analysis. This capability enables businesses to track trends, identify recurring issues, and make informed decisions to improve packaging processes. The ability to analyze data in real-time enhances overall efficiency.

Streamlined Quality Control

With the SeamCheck Plus, quality control processes are streamlined. The device’s automated features and user-friendly interface make it easier to maintain high standards without extensive manual intervention. This streamlining helps in maintaining consistent quality while reducing the time and effort required for inspections.

Applications in Various Industries

Food and Beverage

In the food and beverage industry, packaging quality is paramount for ensuring product safety and extending shelf life. The SeamCheck Plus provides the necessary precision and reliability for inspecting packaging seams, making it an essential tool for this industry.

Pharmaceutical

The pharmaceutical industry requires stringent packaging standards to ensure the safety and efficacy of medications. The SeamCheck Plus helps maintain these high standards by providing accurate and consistent double seam inspections.

Consumer Goods

For consumer goods, packaging plays a crucial role in brand perception and product protection. The SeamCheck Plus helps ensure that packaging meets high-quality standards, enhancing the overall consumer experience.

FAQ

What is the SeamCheck Plus?

The SeamCheck Plus is an automatic double seam projector designed for precise inspection and measurement of packaging seams, enhancing quality and efficiency in packaging processes.

How does the SeamCheck Plus improve packaging quality?

The SeamCheck Plus improves packaging quality by providing accurate double seam inspections, ensuring consistency, and reducing defects in packaging.

What industries benefit from using the SeamCheck Plus?

Industries such as food and beverage, pharmaceutical, and consumer goods benefit significantly from using the SeamCheck Plus due to its precise inspection capabilities.

How does the SeamCheck Plus boost packaging efficiency?

The SeamCheck Plus boosts packaging efficiency through faster inspection times, automated measurement processes, and seamless data integration and analysis.

Can the SeamCheck Plus integrate with existing packaging systems?

Yes, the SeamCheck Plus can integrate with existing packaging systems, providing valuable data and enhancing overall quality control processes.

For more information on the SeamCheck Plus and how it can enhance your packaging processes, visit the SeamCheck Plus product page.