Click for full sized image

A precision instrument designed to measure fill height and brimful volume in various containers, enhancing quality control in packaging with automated adjustments and durable construction. It is user-friendly, versatile, and meets ISO 8106 accuracy standards.

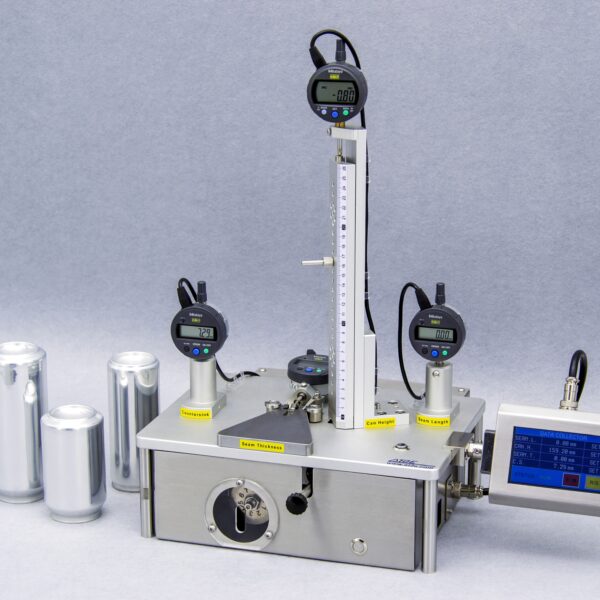

The FHT-1 Fill Height Tester is designed to provide accurate and repeatable measurements of fill height and brimful volume in various containers, improving quality control in packaging.

The FHT-1 utilizes a high-precision liquid level detection system to measure both fill height and brimful volume. Its automated adjustments accommodate different bottle specifications, ensuring optimal results.

Equipped with a 7-inch touchscreen and multiple measuring modes, the FHT-1 is straightforward to operate. The device includes automated volume correction based on water density and temperature, delivering precise measurements consistently.

The FHT-1 is suitable for a variety of containers, including glass and PET bottles. It offers flexible mode settings and can store data for up to 30 products. The stainless steel construction ensures durability and reliability in demanding environments.

The FHT-1 meets the accuracy requirements of ISO 8106 and is compatible with various in-house standards, accommodating the specific measuring needs of different enterprises.

The FHT-1 Fill Height Tester is designed to accurately measure the fill height and brimful volume of various containers, ensuring quality control in packaging processes. It is particularly useful in industries that require precise liquid level measurements.

The FHT-1 employs a high-precision liquid level detection system that automatically adjusts to different bottle specifications. It also features automated volume correction based on water density and temperature, which contributes to its accuracy.

Yes, the FHT-1 is user-friendly, featuring a 7-inch touchscreen interface and multiple measuring modes. Its design allows for straightforward operation, even for users with minimal technical expertise.

The FHT-1 is versatile and can measure a variety of containers, including glass and PET bottles. It can accommodate different dimensions with a sample range of diameters from 55 mm to 203 mm and heights from 150 mm to 440 mm.

Key features include automatic detection of bottle height and fill volume, automated water temperature monitoring, memory storage for up to 30 products, and a stainless steel construction for durability. It also has an integrated PLC for efficient control and operation.

Yes, optional accessories for the FHT-1 include a calibration pack, a mini-printer for printing measurement results, and QualiVol data management software for enhanced data handling and analysis.

A precision instrument designed to measure fill height and brimful volume in various containers, enhancing quality control in packaging with automated adjustments and durable construction. It is user-friendly, versatile, and meets ISO 8106 accuracy standards.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.