Click for full sized image

An automated solution designed for precise sectioning and weighing of bottles, enhancing quality control analysis by ensuring consistent accuracy and reliability. It can cut and weigh up to six sections of a PET bottle, with full automation of the process.

Automatic Bottle Section Cutter and Weighing Device for Quality Control Analysis

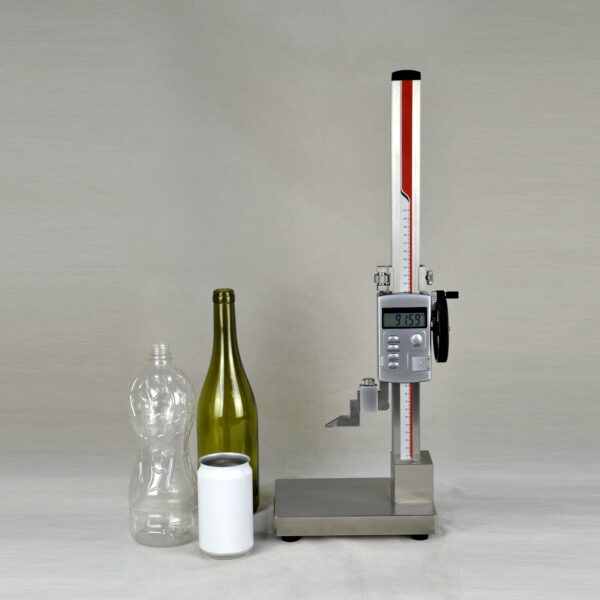

The AT2E ACWD-50 Automatic Bottle Cutting & Weighing Device with Auto Sampling offers an efficient and cost-effective solution for cutting various container shapes for section weight analysis. This device automates bottle feeding, cutting, and weighing processes, ensuring cutting precision and consistency, which enhances analysis accuracy and provides more reliable data. The ACWD-50 can cut a PET bottle into up to six predetermined sections and automatically weigh each section.

Technical Specifications:

Optional:

The ACWD-A is designed for the automated cutting and weighing of PET bottles, facilitating precise sectioning for quality control analysis. It enhances accuracy and reliability in measuring the weight of different sections of a bottle, making it an essential tool in packaging and beverage industries.

The ACWD-A can cut a PET bottle into up to six predetermined sections, allowing for detailed weight analysis of each section, which is crucial for maintaining quality standards.

The ACWD-A has a sample height capacity of up to 14.6 inches (370 mm) and can accommodate diameters ranging from 1.2 to 6.5 inches (30 to 165 mm). It features a weighing range of 0 to 17.6 ounces (0 to 500 g) with a resolution of 0.0004 ounces (0.01 g). The device operates on a power supply of 110 V 60 Hz or 220 V 50 Hz and requires an air supply of 5 to 8 bar (73 to 116.0 psi).

Yes, the ACWD-A is compatible with the optional QUALIWEIGH software, which allows users to analyze and manage the weighing data efficiently, enhancing the overall quality control process.

Optional features for the ACWD-A include supports (bars/grippers) for accommodating different neck sizes, access to large format samples upon request, and the QUALIWEIGH software for data analysis and management.

The ACWD-A has a net weight of 1060 lbs (480 kg) and overall dimensions of 124 x 48 x 93 inches (3150 x 1200 x 2355 mm), making it a robust and substantial piece of equipment designed for industrial use.

An automated solution designed for precise sectioning and weighing of bottles, enhancing quality control analysis by ensuring consistent accuracy and reliability. It can cut and weigh up to six sections of a PET bottle, with full automation of the process.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.

Reviews

There are no reviews yet.