Click for full sized image

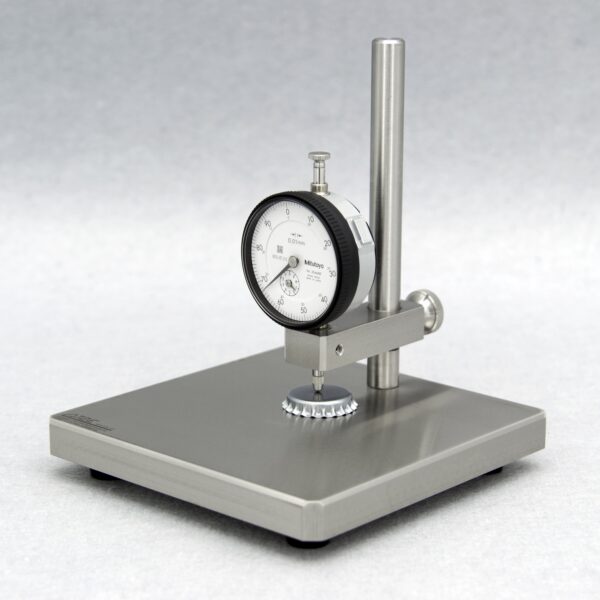

AT2E’s MCG-1 Mouth Clearance Gauge was designed to measure the mouth clearance of several types, sizes and formats of bottles and containers, making it essential for quality control in the packaging and beverage industries. Its versatile design accommodates various bottle shapes and sizes, ensuring precise and reliable results.

AT2E’s MCG-1 Mouth Clearance Gauge was designed to measure the mouth clearance of several types, sizes and formats of bottles and containers.

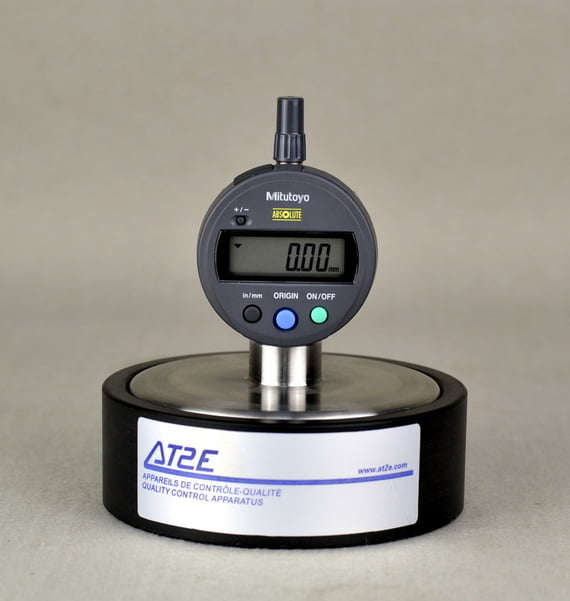

When fitted with automatic calculator (optional for UPBT-1 and UBPT-1D, standard for UBPT-1S), data can be stored and read easily. The MAX, MIN, and SAD (Sum of absolute difference between “MAX” and “MIN”) values will be displayed on the gauge, convenient for the operator.

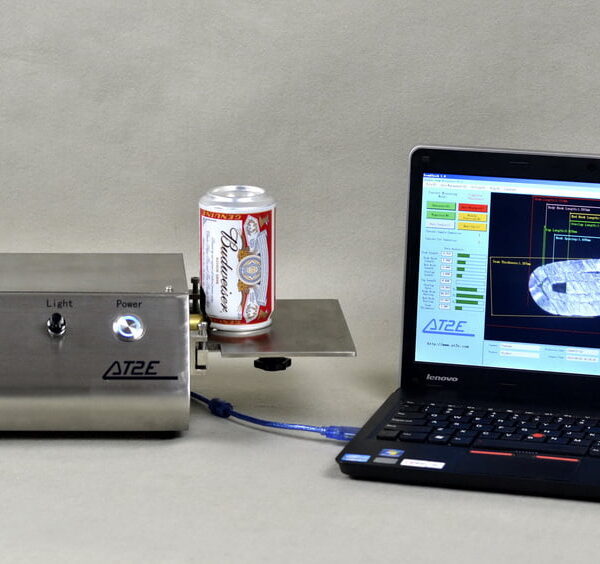

With the optional QUALIGAUGE software, the data can be exported to a PC computer, for further data review and processing by users, and the results can be analyzed via charts and reports.

Technical specifications:

Automatic Calculador Features:

Optional Items:

The MCG-1 Mouth Clearance Gauge is designed to measure the mouth clearance of various types, sizes, and formats of bottles and containers, making it versatile for use in the packaging and beverage industries.

The MCG-1 has a measuring range of 0 – 10 mm with a resolution of 0.01 mm. It offers high accuracy with a digital gauge accuracy of ± 0.01 mm and repeatability of ± 0.05 mm, ensuring precise measurement results.

Yes, when equipped with the optional automatic calculator, the MCG-1 can store and display measurement data including the current value (REAL), maximum value (MAX), minimum value (MIN), and the sum of absolute differences (SAD) between the MAX and MIN values.

Yes, the MCG-1 can be used with the optional QUALIGAUGE software, allowing users to export measurement data to a PC for further analysis, including generating charts and reports.

The MCG-1 measures 350 x 400 x 630 mm (L x W x H) and has a net weight of 22 kg, making it a sturdy and reliable tool for quality control.

Optional items for the MCG-1 include a Verification Column, QUALIGAUGE Software for data analysis, and an Automatic Calculator to facilitate data storage and display.

AT2E’s MCG-1 Mouth Clearance Gauge was designed to measure the mouth clearance of several types, sizes and formats of bottles and containers, making it essential for quality control in the packaging and beverage industries. Its versatile design accommodates various bottle shapes and sizes, ensuring precise and reliable results.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.