Click for full sized image

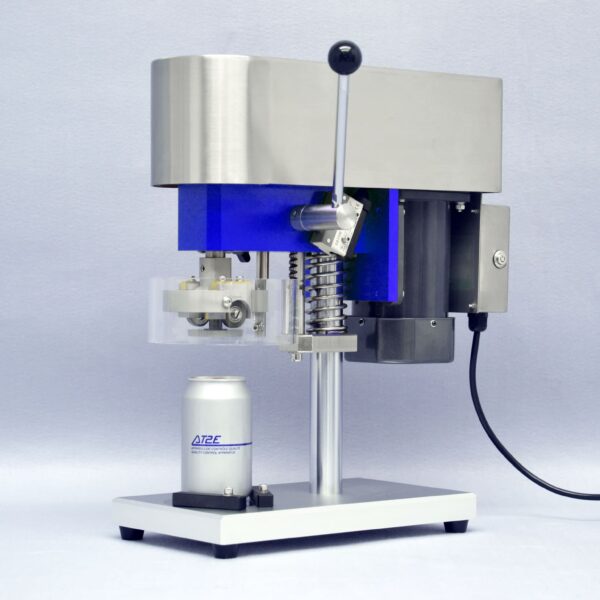

A lightweight tool designed for accurately measuring can seam thickness and length, ideal for quality control in the canning industry. Available in different models, it suits various types of cans, including tin, aluminum, and aerosol.

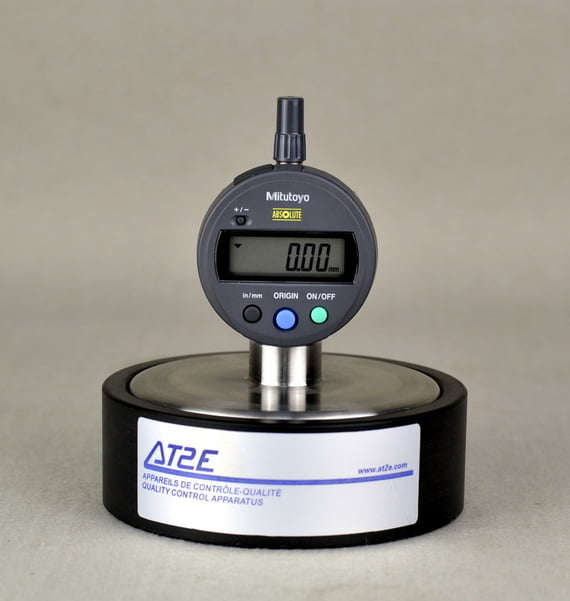

The CSM Can Seam Micrometer is a vital tool for precise and quick measurement of can seam thickness and length, widely used in the canning industry for quality control.

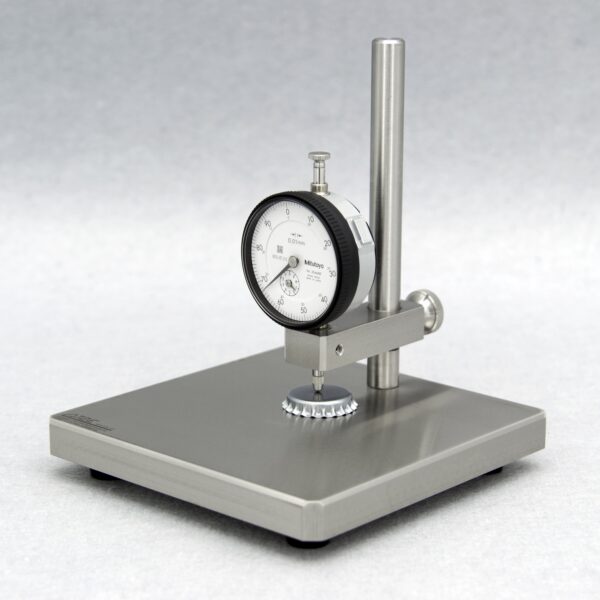

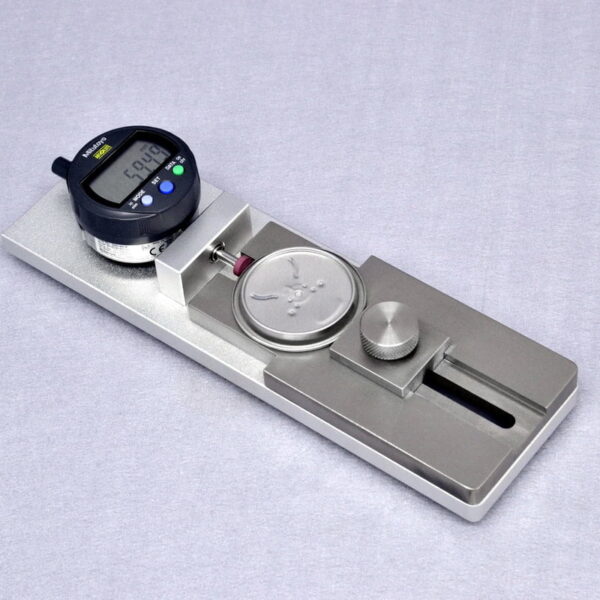

With a measuring range of 0 to 13.00 mm and a resolution of 0.01 mm, the CSM provides accurate and dependable results. It’s suitable for measuring both 3-piece and 2-piece cans, offering versatility across different can types.

Weighing just 0.2 kg, the CSM is lightweight and easy to handle, making it simple to operate. Its robust construction ensures durability, allowing for long-term use in demanding industrial environments.

The CSM Can Seam Micrometer comes in different models: CSM-A for tin cans, CSM-B for aluminum cans, and CSM-C for aerosol cans, making it adaptable to various canning requirements.

The CSM Can Seam Micrometer is designed for accurately measuring the thickness and length of can seams, making it an essential tool for quality control in the canning industry. It ensures that seams meet industry standards for safety and performance.

The CSM Can Seam Micrometer offers a measuring range of 0 to 13.00 mm with a resolution of 0.01 mm and an accuracy of ± 3 µm. It is lightweight at just 0.2 kg, making it easy to handle, and it is suitable for measuring both 3-piece and 2-piece cans.

Yes, the CSM Can Seam Micrometer is available in three models: CSM-A for tin cans, CSM-B for aluminum cans, and CSM-C for aerosol cans. This variety allows it to cater to different canning requirements effectively.

The CSM Can Seam Micrometer is constructed with robust materials to ensure durability, making it suitable for long-term use in demanding industrial environments. Its lightweight design does not compromise its sturdiness.

The CSM Can Seam Micrometer is ideal for quality control in the canning industry, where precise measurements of can seams are critical. It is versatile enough to be used with various can types, including tin, aluminum, and aerosol cans.

Yes, the CSM Can Seam Micrometer is designed with user-friendliness in mind. Its lightweight build and intuitive operation make it simple for users to take accurate measurements quickly and efficiently.

A lightweight tool designed for accurately measuring can seam thickness and length, ideal for quality control in the canning industry. Available in different models, it suits various types of cans, including tin, aluminum, and aerosol.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.

Monday – Friday

06:00 AM – 06:00 PM

US Central Time

AT2E-USA Inc.

2835 N. Sheffield Ave.

Suite 237

Chicago IL 60657 USA