Click for full sized image

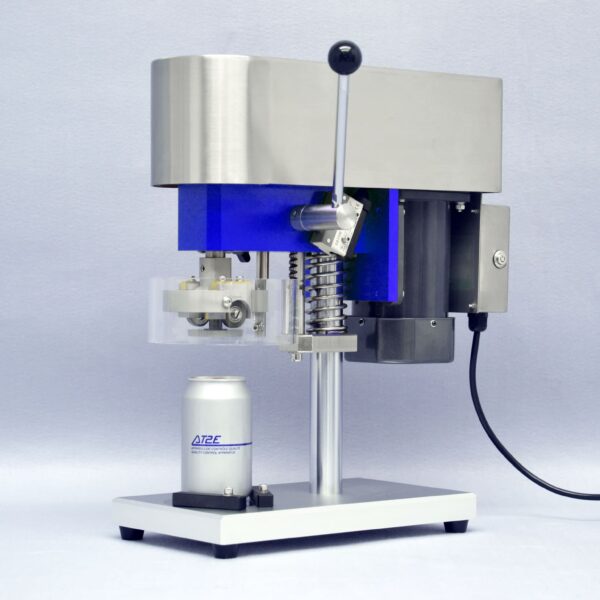

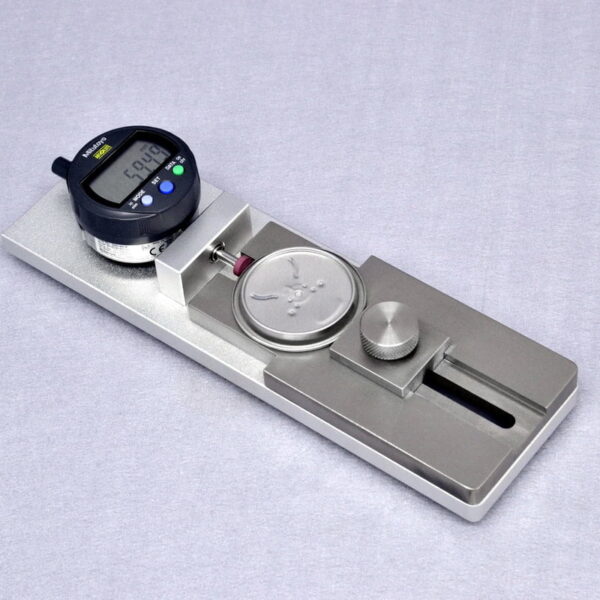

A precision inspection device designed to deliver accurate seam measurements and streamline packaging quality control with its advanced automatic features and user-friendly interface. It supports a range of measurement parameters and integrates seamlessly into various production environments to enhance productivity.

The SeamCheck Plus Double Seam Projector offers precise and efficient seam inspections, ensuring your packaging processes meet high standards.

The SeamCheck Plus Automatic Seam Projector uses advanced technology to provide accurate seam measurements, maintaining product quality and integrity.

The device features an easy-to-use interface, suitable for various production environments.

Incorporating SeamCheck Plus into your workflow boosts productivity and reduces inspection time, with automatic features enabling continuous operation.

The SeamCheck Plus is a precision inspection device designed to deliver accurate seam measurements for packaging quality control. It ensures that packaging processes meet high standards, maintaining product quality and integrity.

The SeamCheck Plus features an auto-measure function that completes seam measurements in just 1 second, significantly enhancing efficiency in the inspection process.

The SeamCheck Plus can analyze a variety of measurement parameters including seam length, body hook length, end hook length, overlap, seam gap, overlap rate, body hook lapping rate, end hook lapping rate, and on-screen seam thickness.

Yes, the SeamCheck Plus allows users to export measurement results to Excel, making it easy to manage and analyze data for reporting purposes.

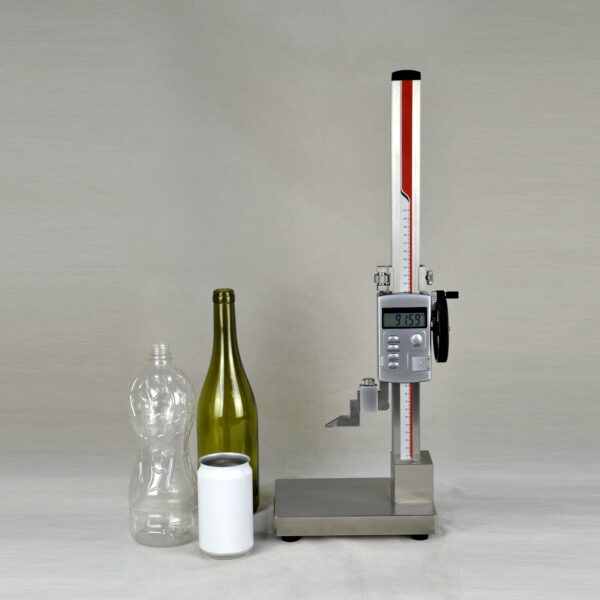

The SeamCheck Plus has a resolution of 0.005 mm, an accuracy of 60X magnification, and can accommodate up to 180 mm diameter cans. It operates on a power supply of 100 – 240 V and has dimensions of 420 (L) x 200 (W) x 95 (H) mm, weighing 5 kg.

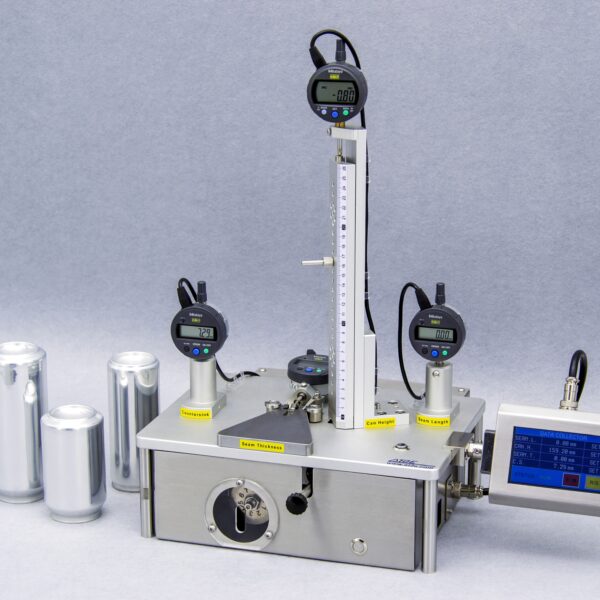

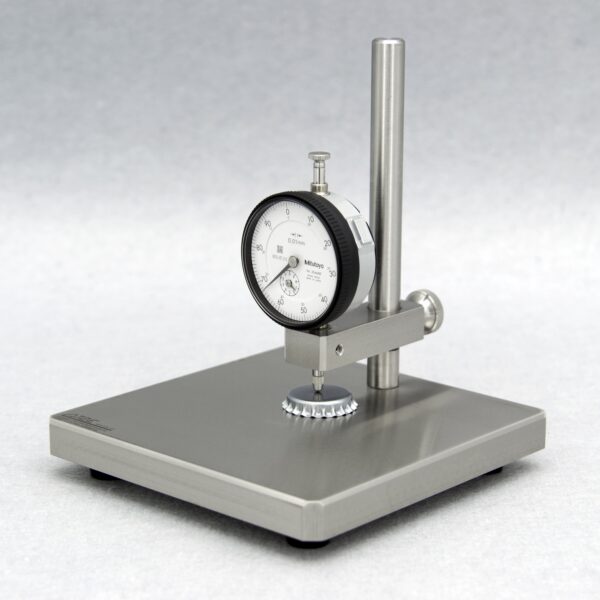

Optional parts include various gauges such as the STG-1 Seam Thickness Gauge, CG-D Countersink Gauge, and HG-1 Height Gauge, as well as cutting saws and a data transport box to enhance the functionality of the SeamCheck Plus.

A precision inspection device designed to deliver accurate seam measurements and streamline packaging quality control with its advanced automatic features and user-friendly interface. It supports a range of measurement parameters and integrates seamlessly into various production environments to enhance productivity.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.

Monday – Friday

06:00 AM – 06:00 PM

US Central Time

AT2E-USA Inc.

2835 N. Sheffield Ave.

Suite 237

Chicago IL 60657 USA