Click for full sized image

For a precise and quick measuring of four seam dimensions in cans

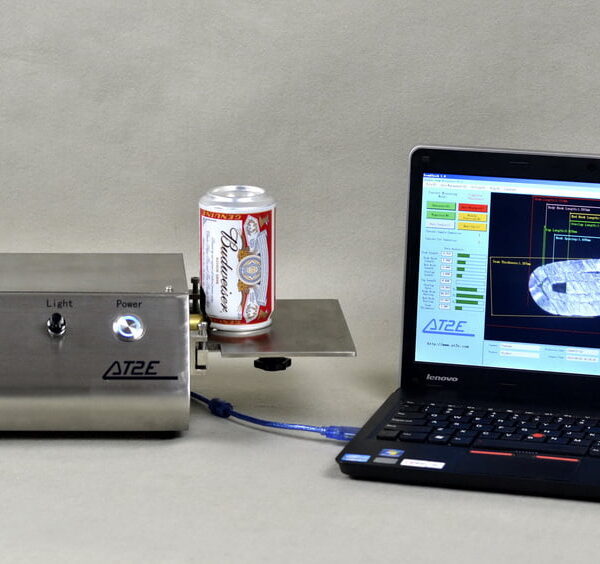

The DSMM-1 Double Seam Measuring Minidesk offers a precise, quick, easy and accurate measurement of can seams, essential for maintaining quality in can manufacturing.

AT2E’s DSMM-1 Double Seam Measuring Minidesk was designed to measure four seam dimensions (seam thickness, seam length / seam height, countersink and can height) all together in just one second.

Operator just needs to position the can on the table support to get all the measurement. It provides a fast, repeatable and accurate measuring procedure for operator.

The DSMM-1 can work for both beverage and food cans. With the optional data transporting box, all measurement result can be sent to a data collection software or AT2E’s special software or AT2E SeamCheck software.

Technical specifications:

Optional parts:

The DSMM-1 Double Seam Measuring Minidesk is designed to measure four key seam dimensions in cans, including seam thickness, seam length, countersink, and can height. This tool is essential for ensuring quality control in can manufacturing for both beverage and food cans.

The DSMM-1 allows operators to measure all four seam dimensions in just one second by simply positioning the can on the table support. This fast and repeatable process significantly enhances measurement efficiency in manufacturing environments.

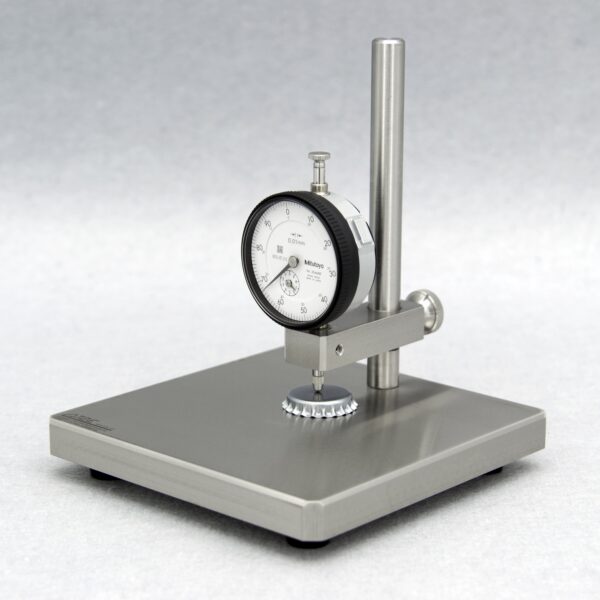

The DSMM-1 has a measuring range for seam thickness and seam length of 0 – 4 mm, countersink up to 8 mm, and can height from 80 – 250 mm. It boasts an accuracy of 0.02 mm and a display resolution of 0.01 mm. The device dimensions are 495 x 295 x 520 mm, and it weighs 11 kg.

Yes, the DSMM-1 can be equipped with an optional data transporting box that allows all measurement results to be sent to data collection software, including AT2E’s special software and SeamCheck software, facilitating better data management and analysis.

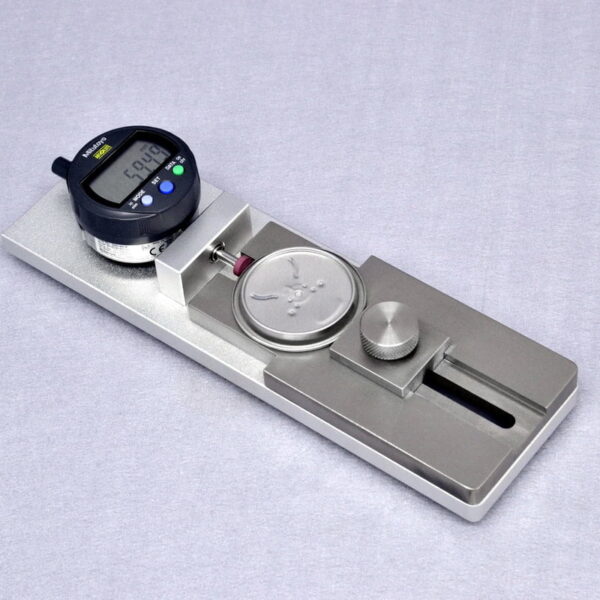

Optional accessories for the DSMM-1 include a data collector box with cables and AT2E’s software, which enhances functionality and enables more efficient data handling.

The DSMM-1 offers high accuracy with a measurement precision of 0.02 mm, ensuring reliable and precise measurements for can seams, which is crucial for maintaining quality in production.

For a precise and quick measuring of four seam dimensions in cans

The DSMM-1 Double Seam Measuring Minidesk offers a precise, quick, easy and accurate measurement of can seams, essential for maintaining quality in can manufacturing.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.

Monday – Friday

06:00 AM – 06:00 PM

US Central Time

AT2E-USA Inc.

2835 N. Sheffield Ave.

Suite 237

Chicago IL 60657 USA