Click for full sized image

A precision tool designed for the food and beverage canning industries, offering fast, accurate measurements of aluminum can seams with advanced software integration for detailed data analysis and reporting. Its user-friendly design supports various can sizes and includes optional accessories for enhanced functionality.

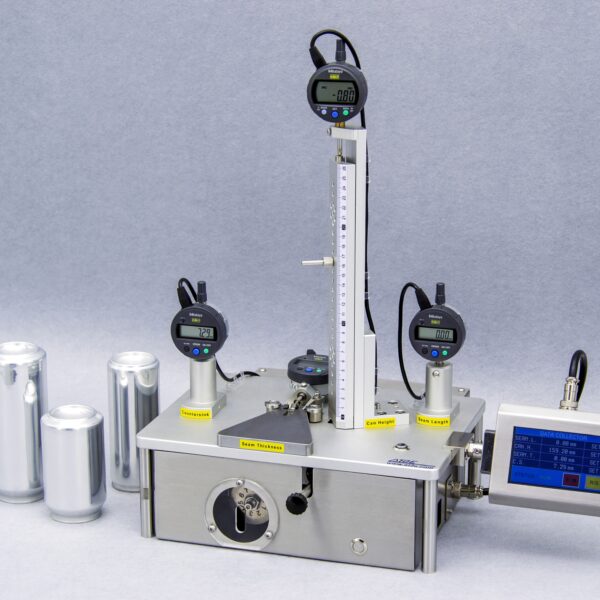

SeamCheck Automatic Double Seam Projector

Enhance your seam inspection process with the SeamCheck Automatic Double Seam Projector, designed specifically for the beverage and food canning industries. This tool delivers fast, precise measurements of aluminum can seams, ensuring high-quality results every time.

Key Features:

Fast and Accurate Seam Measurement

SeamCheck Software Integration

Versatile and User-Friendly

Enhanced Functionality with Optional Tools

Specifications:

Included Equipment:

Optional Accessories:

Additional Features:

The SeamCheck Automatic Double Seam Projector is specifically designed for the food and beverage canning industries to provide fast and accurate measurements of aluminum can seams. It ensures high-quality results and helps maintain product integrity through precise seam inspections.

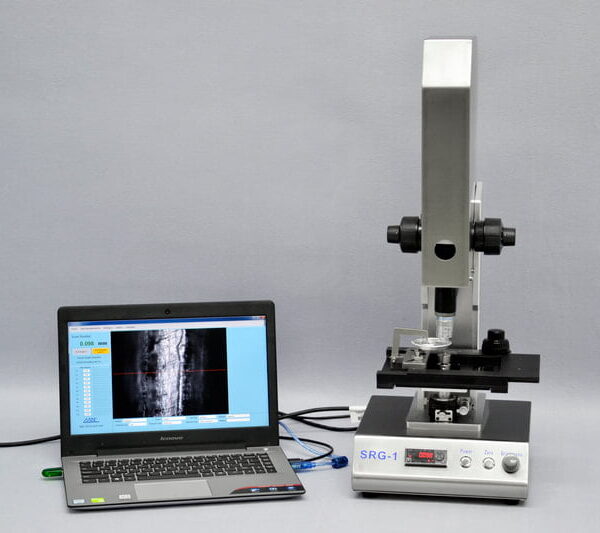

The SeamCheck software integrates with the projector to save and manage measurement data, allowing for easy review and analysis. It supports Statistical Process Control (SPC) compatibility and can export data in Excel format for detailed reporting, facilitating a more efficient quality control process.

The SeamCheck features a resolution of 0.001 mm and an accuracy of 0.005 mm, making it suitable for various can sizes up to 180 mm in diameter. It operates on a power supply of 220 V and has a serial interface of RS 232. The dimensions are 470 mm x 200 mm x 125 mm, and it weighs 5 kg (11 lbs).

Yes, the SeamCheck can be paired with AT2E’s proprietary seam saws and other optional accessories like the STG-1 Seam Thickness Gauge and CG-D Countersink Gauge. These tools enhance the functionality of the SeamCheck by providing clear seam section images and additional measurement capabilities.

The SeamCheck can measure up to 9 standard seam parameters, with the option to extend to 12 parameters. It also includes predefined qualification standards that automatically assess results and provide warnings if measurements fall outside specifications.

Yes, calibration can be performed at any time using the provided calibration piece. This ensures that the measurements remain accurate and reliable, which is crucial for maintaining quality standards in the canning process.

A precision tool designed for the food and beverage canning industries, offering fast, accurate measurements of aluminum can seams with advanced software integration for detailed data analysis and reporting. Its user-friendly design supports various can sizes and includes optional accessories for enhanced functionality.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.