Click for full sized image

A precision instrument designed for testing the seal integrity of caps on preforms, featuring a multi-station design, PLC control, and advanced pressurization capabilities for accurate and reliable performance assessment.

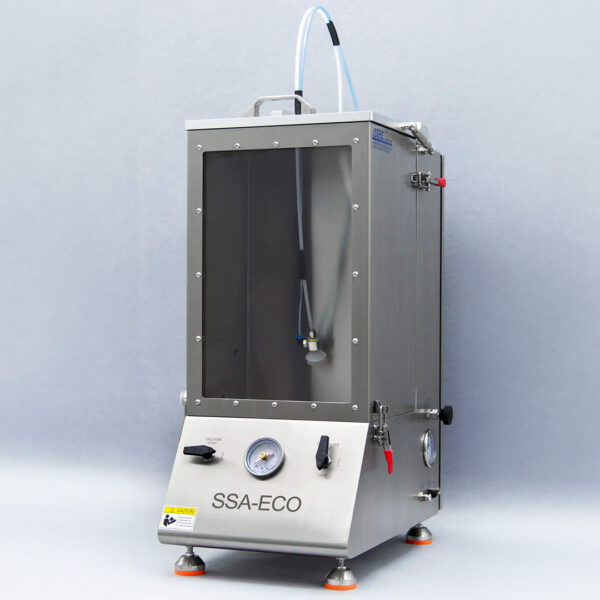

The SSA-PLC-12 Secure Seal Analyzer (12 Positions) is a specialized instrument designed by AT2E to evaluate the secure seal performance of caps on preforms.

This updated model features a new design based on practical experience, offering improved integration and ease of operation compared to previous versions. The redesigned structure also simplifies maintenance.

Key Features:

Technical Specifications:

The SSA-PLC-12 Secure Seal Analyzer is designed to test the seal integrity of caps on preforms, ensuring that they meet quality standards for packaging. It provides reliable performance assessments through advanced pressurization capabilities and multi-station testing.

The multi-station design allows users to conduct tests on multiple samples simultaneously, significantly increasing throughput and efficiency in the testing process. Each of the 12 positions can be individually controlled to suit specific testing needs.

The SSA-PLC-12 has a measurement range of 0.00 – 16.00 bar (up to 232 psi) with an accuracy of ± 0.5% of full scale. It features a 7-inch LCD touchscreen for easy operation, supports up to 4 pressurization steps, and has a maximum testing pressure of 16 bar.

Yes, the SSA-PLC-12 is designed with ease of maintenance in mind. Its updated structure simplifies routine cleaning and maintenance tasks, ensuring that the instrument remains in optimal working condition.

The SSA-PLC-12 features a stainless steel frame for durability and safety, along with a removable water bath that has an anti-explosion design. This ensures safe monitoring of samples during testing and minimizes risks during operation.

Yes, the SSA-PLC-12 is specially designed to test the sealing performance of various types of caps on preforms, making it a versatile tool for quality control in packaging applications.

A precision instrument designed for testing the seal integrity of caps on preforms, featuring a multi-station design, PLC control, and advanced pressurization capabilities for accurate and reliable performance assessment.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.