Click for full sized image

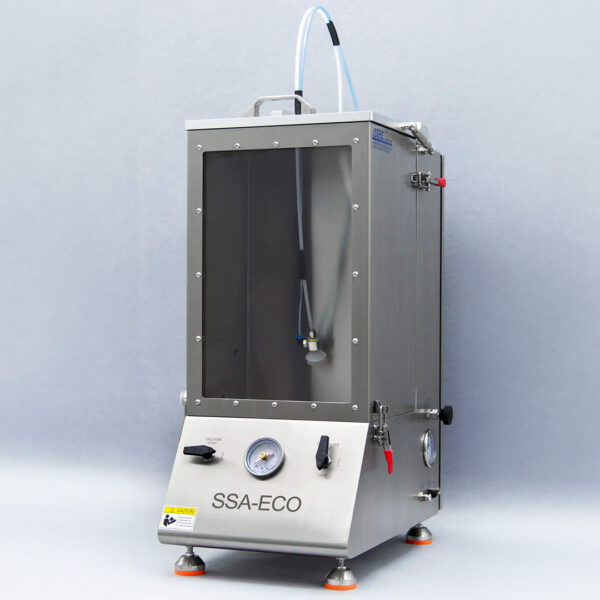

A manual tool designed for precise and repeatable cutting of PET bottle sections, essential for accurate section weight analysis in quality control processes. It is portable, safe, and reduces maintenance costs compared to electrical models.

The SSC-1 Simple Section Cutter is designed to simplify the process of cutting PET bottle sections for weight analysis. This tool ensures precise and consistent cuts, making it essential for quality control in bottle manufacturing.

The SSC-1 Simple Section Cutter is a cost-effective solution for producing consistent PET bottle sections, crucial for maintaining uniform section weights.

Note:

Please provide bottle drawing and demanded section dimension upon order.

The SSC-1 Simple Section Cutter is specifically designed for cutting PET bottle sections to facilitate accurate weight analysis in quality control processes within the bottle manufacturing industry.

The operation is straightforward: you insert the bottle into the cutter, press the lever to position the knife, and then twist the bottle to achieve the desired section. This simple process ensures efficiency and precision in cutting.

The SSC-1 offers several advantages, including lower maintenance costs, portability, and safety. Unlike electrical models, it does not emit harmful gases and can be used in various settings without needing a power source.

Yes, the SSC-1 requires less maintenance compared to electrical cutting tools, making it a cost-effective and practical choice for consistent and precise cutting of PET bottle sections.

When placing an order, please provide the bottle drawing and the required section dimensions to ensure that the cutter meets your specific needs.

Yes, the SSC-1 is portable and versatile, making it suitable for use in different environments, from manufacturing plants to quality control labs, without the need for electrical power.

A manual tool designed for precise and repeatable cutting of PET bottle sections, essential for accurate section weight analysis in quality control processes. It is portable, safe, and reduces maintenance costs compared to electrical models.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.