Click for full sized image

The UBPT-3 Universal Bottle Perpendicularity Tester precisely measures perpendicularity deviation, mouth clearance, and height of symmetric containers, making it an essential tool for quality control in the packaging and beverage industries.

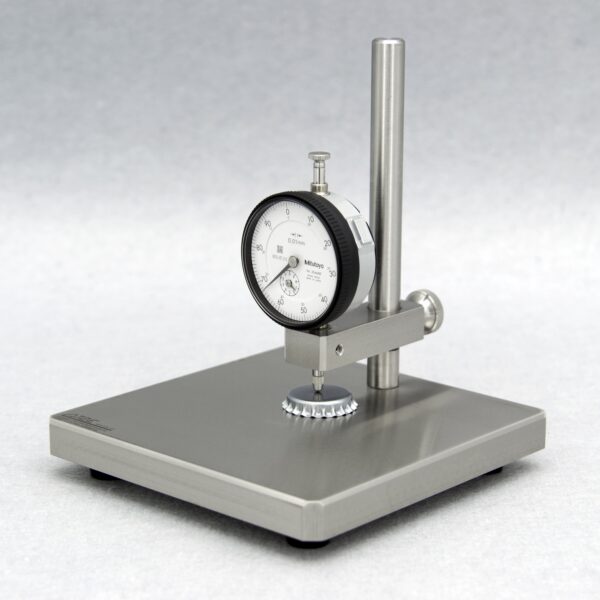

UBPT-3 Universal Bottle Perpendicularity Tester with Mouth and Height Gauges

The UBPT-3 Universal Bottle Perpendicularity Tester is designed to precisely measure perpendicularity deviations in symmetric containers. Additionally, it measures mouth clearance and bottle height, making it essential tool for quality control in the packaging and beverage industries.

### Precise Measurement

With a high-resolution gauge offering measurements with a precision of 0.01 mm, the UBPT-3 ensures consistently reliable results.

### Versatile Use

The tester accommodates a wide range of bottle sizes, from 30 to 150 mm in diameter and 112 to 400 mm in height, making it adaptable to various testing requirements.

### User-Friendly Interface

Featuring an intuitive interface and easy-to-read measurements, the UBPT-3 allows operators to perform tests efficiently and with confidence.

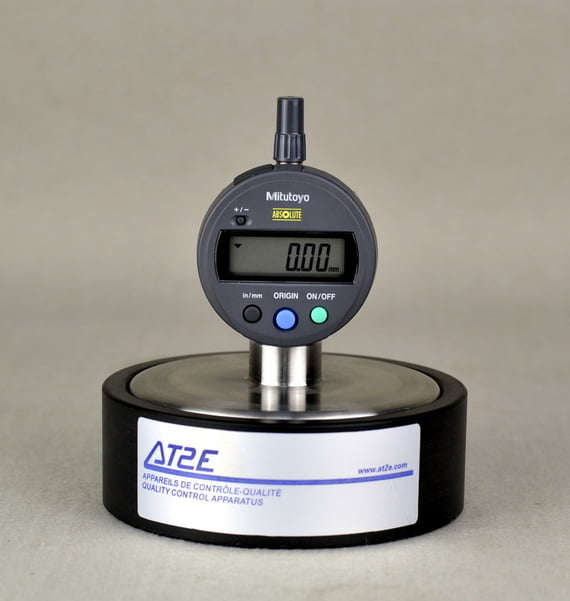

Optional add-ons: For enhanced functionality, an optional automatic calculator is available (sold separately or integrated into certain models). This calculator enables easy data transmission, displaying MAX, MIN, and SAD (Sum of Absolute Differences between MAX and MIN) values for convenient operator reference.

Technical specifications:

|

The UBPT-3 Universal Bottle Perpendicularity Tester is designed to measure perpendicularity deviations, mouth clearance, and height of symmetric containers. It is a crucial tool for quality control in the packaging and beverage industries, ensuring that bottles meet specified standards.

The UBPT-3 has a sample range of 30 to 150 mm in diameter and a height range of 112 to 400 mm. It features a measuring range of 0 – 10 mm with a resolution of 0.01 mm, providing precise measurements for various bottle sizes.

Yes, the UBPT-3 can be equipped with an optional automatic calculator, which allows for easy data transmission and displays important values such as maximum (MAX), minimum (MIN), and the sum of absolute differences (SAD) for convenient reference during testing.

Absolutely! The UBPT-3 features a user-friendly interface with easy-to-read measurements, making it simple for operators to perform tests efficiently and with confidence.

In addition to the automatic calculator, users can inquire about larger size options for both diameter and height measurements to enhance the versatility of the tester for different container types.

The UBPT-3 offers high precision with a resolution of 0.01 mm, ensuring that measurements of perpendicularity, mouth clearance, and height are consistently reliable and accurate.

The UBPT-3 Universal Bottle Perpendicularity Tester precisely measures perpendicularity deviation, mouth clearance, and height of symmetric containers, making it an essential tool for quality control in the packaging and beverage industries.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.