Click for full sized image

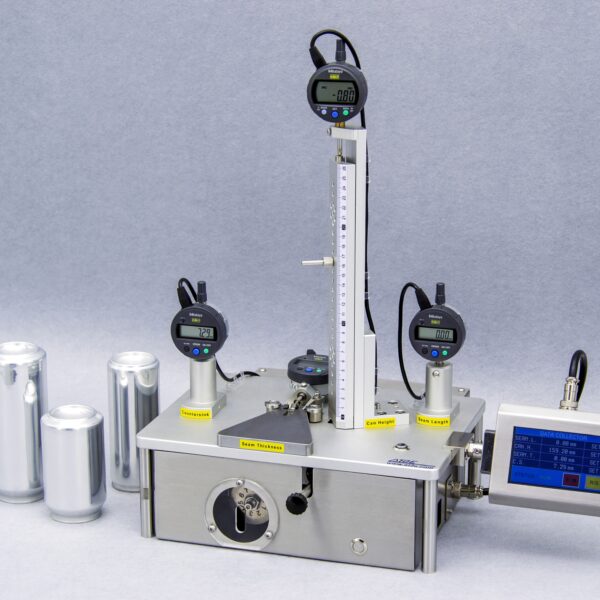

Designed to measure the countersink depth of aluminum cans with an accuracy of ±0.01 mm, supporting seamless data transfer for efficient quality control. It is versatile, user-friendly, and essential for maintaining the quality and consistency of 3-piece and 2-piece cans and ends.

Accurate Countersink Gauge for Precise Can Measurements – CG-D

Ensure the quality and consistency of your aluminum cans with our digital Countersink Gauge. Designed for precise measurement of countersink depth, this gauge provides quick and easy assessments essential for quality control in can and end production.

High Precision and Versatility

The digital Countersink Gauge offers a measurement range of 0-12 mm (0-0.47 in), with a resolution of 0.01 mm and an accuracy of ±0.01 mm. This level of precision ensures reliable measurements for both 3-piece and 2-piece cans and ends, making it an essential tool for manufacturers.

Enhanced Data Management

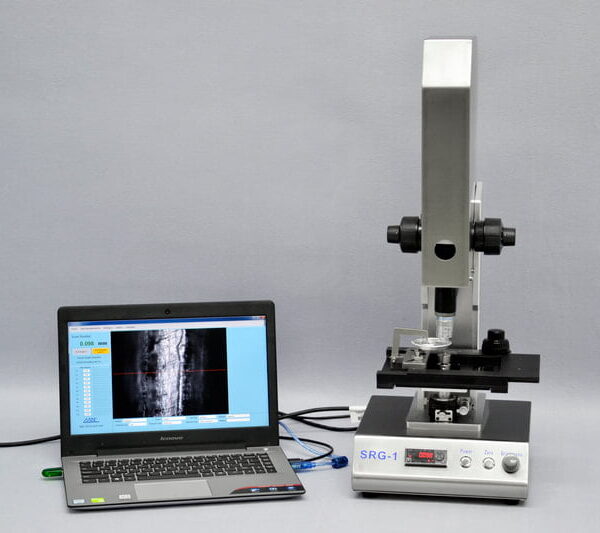

To prevent manual recording errors, the Countersink Gauge can be connected to an SPC system or AT2E’s SeamCheck software via the DTB-1 Data Transporting Box. This allows for seamless data transfer, facilitating accurate and efficient quality control processes where all measurements are correctly logged and analyzed.

User-Friendly and Efficient

Designed for ease of use, the Countersink Gauge includes a ‘zeroization’ base for quick setup and measurement. Its compact, lightweight design makes it easy to handle and operate, ensuring that quality control checks are fast and reliable.

Optimize Your Production Line

The digital Countersink Gauge is the ultimate solution for precise countersink depth measurement in aluminum cans and ends.

Technical Specifications:

The Accurate Countersink Gauge CG-D is designed to measure the countersink depth of aluminum cans with high precision. It is essential for quality control in the production of both 3-piece and 2-piece cans, ensuring that they meet industry standards for consistency and quality.

The CG-D has a measuring range of 0-12 mm (0-0.47 in), with a resolution of 0.01 mm and an accuracy of ±0.01 mm. Its compact size is 147 x 81 x 153 mm (5.79 x 3.19 x 6.02 in) and it weighs only 1 kg (2.2 lbs.), making it easy to handle and operate.

The CG-D can be connected to an SPC system or AT2E’s SeamCheck software via the DTB-1 Data Transporting Box. This feature allows for seamless data transfer, preventing manual recording errors and ensuring that all measurements are accurately logged for efficient quality control processes.

Yes, the CG-D is designed for user-friendliness. It includes a ‘zeroization’ base for quick setup and measurement, allowing operators to perform quality control checks rapidly and reliably without complicated procedures.

The Accurate Countersink Gauge CG-D is versatile and can measure the countersink depth of both 3-piece and 2-piece aluminum cans and ends, making it an essential tool for manufacturers in the beverage and packaging industries.

The CG-D offers high accuracy with a precision of ±0.01 mm, ensuring reliable and consistent measurements that are crucial for maintaining the quality of aluminum cans during production.

Designed to measure the countersink depth of aluminum cans with an accuracy of ±0.01 mm, supporting seamless data transfer for efficient quality control. It is versatile, user-friendly, and essential for maintaining the quality and consistency of 3-piece and 2-piece cans and ends.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.

Reviews

There are no reviews yet.