Click for full sized image

For precisely measuring the seam thickness of cans

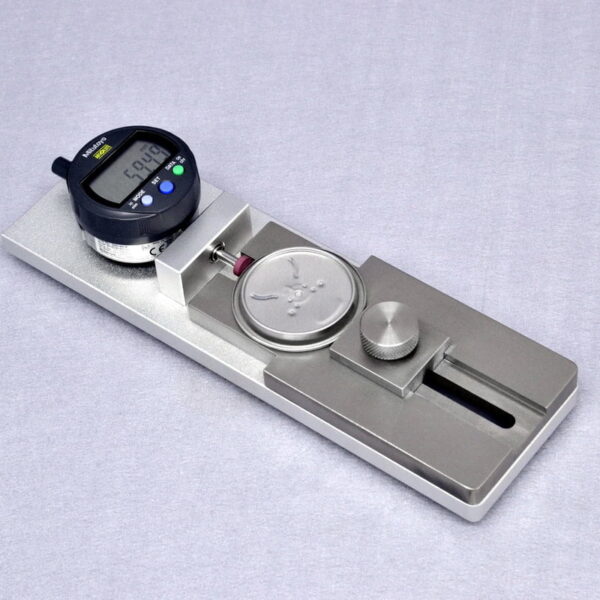

The STG-1 Seam Thickness Gauge offers precise and accurate measurement of can seams, essential for maintaining quality in can manufacturing.

Designed for easy operation, it offers a fast and accurate measurement of seam thickness.

The STG-1 Seam Thickness Gauge is designed for precise measurement of can seam thickness, ensuring high-quality control in the can manufacturing industry. It offers easy operation and fast, accurate measurements.

Precision and Accuracy With a measuring range of 0-6 mm and a resolution of 0.01 mm, the STG-1 ensures accurate readings. The device is compatible with various can sizes, making it versatile for different applications.

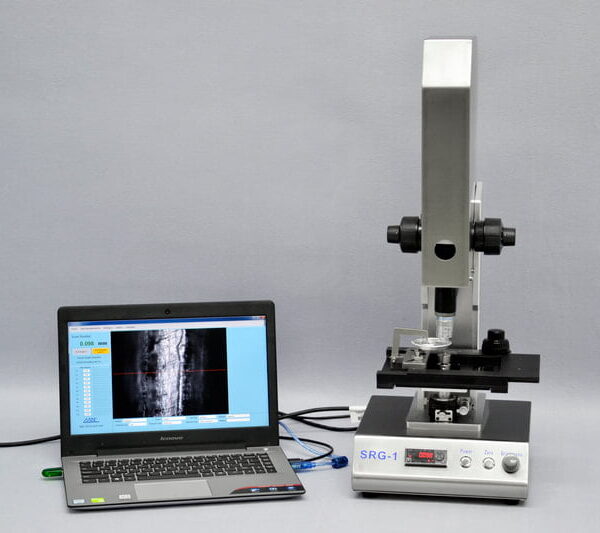

User-Friendly Design The auto-centering feature and adjustable measuring point allow for easy positioning of cans during measurement. Additionally, it can connect to the SPC system or AT2E’s SeamCheck software for data transfer, minimizing manual recording errors.

Essential for Quality Control The STG-1 Seam Thickness Gauge is crucial for maintaining high standards in can manufacturing. Its precise and reliable measurements help ensure that can seams meet industry standards.

With measure angle compensation and adjusted center measuring point, the can may also be easily auto-positioned in the center during measuring. The gauge is applicable for different kinds of cans.

When using the double seam projector, the seam structure may have a slight deformation after being cut by the seaming cutting saw. The seam thickness measured on the projector will, therefore, have a certain deviation. While using the seam thickness gauge, a user is able to measure the actual seam thickness value.

In order to avoid the manual recording error, the gauge can be connected to SPC system or AT2E “SeamCheck” software with DTB-1 Data Transporting Box and cable. The data can then be transferred to SPC system or “SeamCheck” software through DTB-1 and cable.

| Technical specifications | |

|---|---|

| Measuring range | 0-6 mm |

| Resolution | 0.01 mm |

| Accuracy | ±0.01 mm |

| Sample range | 3-pcs & 2-pcs can |

| Sample capacity | 50 mm to 90 mm dia. can (Bigger by order) |

| Overall size | 180(L) x 103(W) x 108(H) mm |

| Net weight | 1 kg |

For precisely measuring the seam thickness of cans

The STG-1 Seam Thickness Gauge offers precise and accurate measurement of can seams, essential for maintaining quality in can manufacturing.

Designed for easy operation, it offers a fast and accurate measurement of seam thickness.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.

Monday – Friday

06:00 AM – 06:00 PM

US Central Time

AT2E-USA Inc.

2835 N. Sheffield Ave.

Suite 237

Chicago IL 60657 USA