Click for full sized image

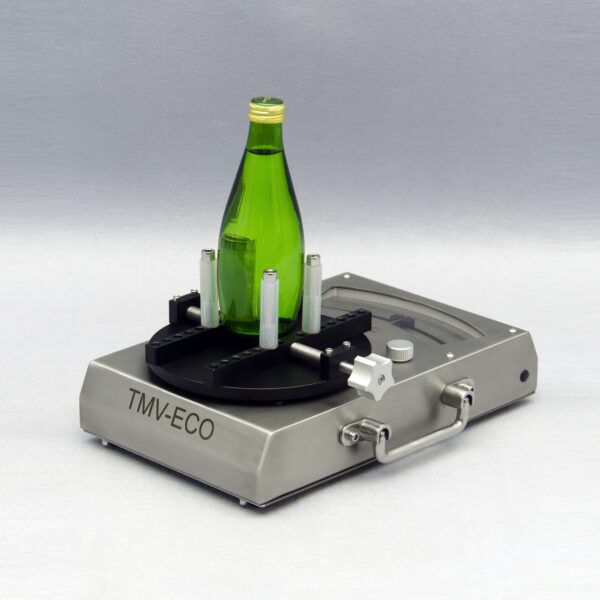

A fully automated, multi-functional system designed for comprehensive quality control in bottled beverages, offering precise testing for torque, weight, seal performance, and other key parameters with minimal operator intervention. Its durable stainless steel construction, user-friendly interface, and compliance with industry standards make it an essential tool for ensuring consistent product quality.

The ADAITS Automated Beverage Tester is a sophisticated solution designed for the comprehensive quality control of bottled beverages. Leveraging over 35 years of industry experience, this automated system conducts precise and reliable tests across various parameters, including torque, weight, and seal performance.

The ADAITS system is equipped with multiple testing modules, each designed to address specific aspects of beverage quality control. These modules include torque testing, weight control, application angle measurement, inner-pressure control, secure seal performance, and top load performance. Each module is built to deliver accurate data collection and analysis, ensuring consistent product quality.

The ADAITS operates seamlessly in an inline environment, performing automatic sampling without the need for manual intervention. This fully automated operation eliminates operator influence, enhancing test reproducibility. The system features a user-friendly touch screen interface, PLC control, and customizable operation screens. It supports up to 30 different product types and can store up to 1,000 test records, making it an efficient tool for quality control.

Constructed from durable stainless steel and featuring a safety door, the ADAITS is designed for both longevity and ease of use. It offers real-time data output and supports multiple languages. The system complies with CFR21-11 / FDA regulations, ensuring it meets industry standards for quality control in bottled beverages.

This revised description should provide a clearer and more detailed overview of the ADAITS Automated Beverage Tester, with measurements included in both metric and imperial units for better comprehension.

The ADAITS Automated Beverage Tester is designed for comprehensive quality control in bottled beverages. It performs precise testing for various parameters, including torque, weight, seal performance, and more, ensuring consistent product quality with minimal operator intervention.

The ADAITS system features advanced testing modules that provide accurate data collection and analysis. Each module is engineered for specific tests, such as torque and weight, with high accuracy rates, ensuring reliable results that comply with industry standards.

Yes, the ADAITS operates fully automated in an inline environment, allowing for automatic sampling without manual intervention. This feature enhances test reproducibility and minimizes the influence of operators on the results.

The ADAITS is constructed from durable stainless steel, designed for long-term use and easy maintenance. It also includes a safety door for added protection during operation.

The system can store up to 1,000 test records, allowing for comprehensive data management and easy access to historical testing information for analysis and quality control purposes.

Yes, the ADAITS complies with CFR21-11 / FDA regulations, ensuring that it meets the necessary industry standards for quality control in bottled beverages.

A fully automated, multi-functional system designed for comprehensive quality control in bottled beverages, offering precise testing for torque, weight, seal performance, and other key parameters with minimal operator intervention. Its durable stainless steel construction, user-friendly interface, and compliance with industry standards make it an essential tool for ensuring consistent product quality.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.

Reviews

There are no reviews yet.