Click for full sized image

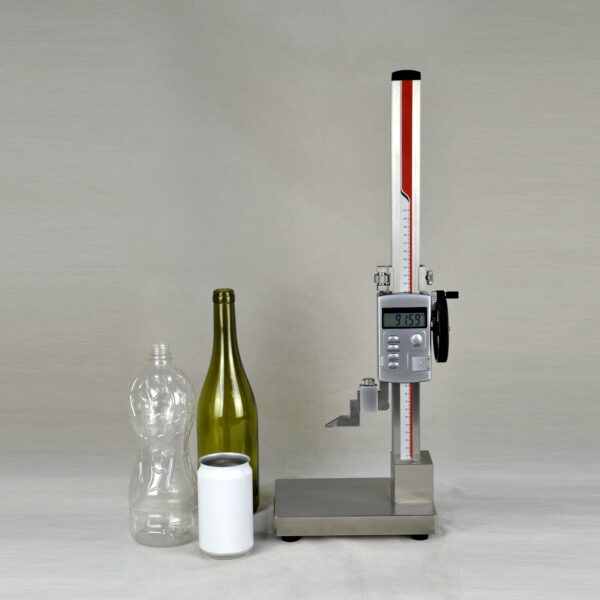

A tool designed to replicate friction and abrasions on packaging lines, enabling true-to-life testing of glass, plastic, and aluminum bottles and cans to ensure product durability and quality. With adjustable parameters and robust construction, it offers versatile testing capabilities for comprehensive quality control.

The Production Line Simulator is an advanced tool specifically designed to simulate friction on a packaging line. This simulator accurately replicates the abrasions caused by bottle contact, making it an essential tool for assessing the quality of glass bottles, their coatings, and labeling.

Key Features and Applications

Efficiently simulate the wear and abrasion on returnable bottles and assess the durability of your packaging with our high-performance Production Line Simulator. Integrate this tool into your quality control processes to ensure the highest quality standards for your products.

Technical Specifications Summary

The PLS – Production Line Simulator is designed to replicate friction and abrasions on packaging lines, allowing for true-to-life testing of glass, plastic, and aluminum bottles and cans. This ensures product durability and quality through comprehensive quality control assessments.

This simulator can test a variety of materials including glass, plastic, and aluminum bottles and cans, making it a versatile tool for different packaging types and ensuring thorough evaluations across all materials.

The Production Line Simulator offers customizable settings for cycle times, speeds, and conveyor border spacing. This allows users to tailor the testing setup according to specific requirements, enhancing the accuracy and relevance of the testing results.

The simulator operates at rotation speeds of 0-20 rpm and accommodates sample diameters ranging from 50 to 150 mm. It requires an AC 220V power supply (with an optional AC 110V available) and has an air supply requirement of 5-8 bar. The dimensions are 47.7″ x 53.4″ x 43.7″, and it weighs 510 lbs (230 kg).

By integrating the Production Line Simulator into quality control processes, companies can efficiently simulate wear and abrasion on returnable bottles, assess packaging durability, and ensure that products meet the highest quality standards before reaching consumers.

Yes, the simulator is constructed from robust stainless steel, ensuring durability and longevity even under rigorous testing conditions. Its design is aimed at withstanding the demands of frequent use in quality control environments.

A tool designed to replicate friction and abrasions on packaging lines, enabling true-to-life testing of glass, plastic, and aluminum bottles and cans to ensure product durability and quality. With adjustable parameters and robust construction, it offers versatile testing capabilities for comprehensive quality control.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.

Monday – Friday

06:00 AM – 06:00 PM

US Central Time

AT2E-USA Inc.

2835 N. Sheffield Ave.

Suite 237

Chicago IL 60657 USA