Click for full sized image

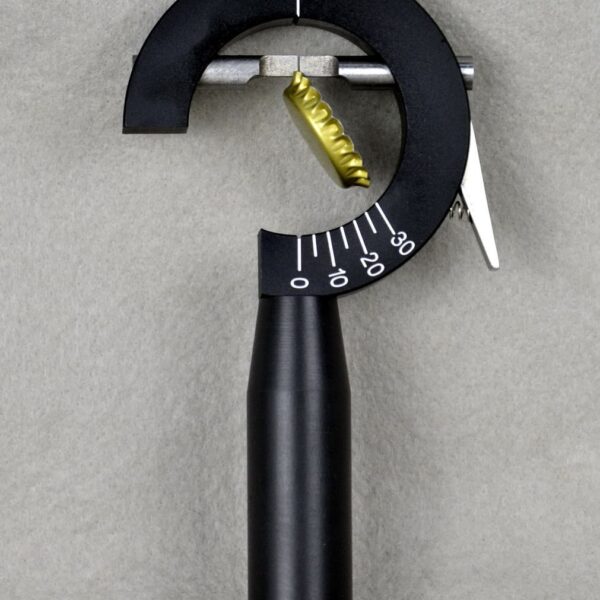

For assessing the durability of metal and coatings on crown caps by measuring wear through controlled tumbling tests.

The AT2E CCTT Tumbling Tester is designed to evaluate the shedding of metal and coating from crown closures. This tool is essential for cap manufacturers, breweries, and quality inspection agencies.

Features:

Testing Procedure:

Technical Specifications:

The CCTT Tumbling Tester is designed to assess the durability of metal and coatings on crown caps by measuring wear through controlled tumbling tests. It is essential for cap manufacturers, breweries, and quality inspection agencies to ensure product quality and compliance with industry standards.

The testing procedure involves dividing 50 cleaned crown caps into two groups of 25, weighing each group, placing them in the dual sample chambers, and running the test for a set time (up to 99 minutes) at a speed of 20 RPM. After the test, the caps are cleaned, reweighed, and the weight loss is calculated to determine the cap’s abrasive wear value.

The CCTT Tumbling Tester features dual sample chambers for increased efficiency, an adjustable timer that can be set for up to 99 minutes, and operates at a tumbling speed of 20 RPM. These features enhance the testing process and provide accurate results.

The technical specifications include a tumbling speed of 20 RPM, time setting from 1 to 99 minutes, two rolling grooves, dimensions of 28.75” x 11” x 17” (730 x 280 x 430 mm), and a weight of 55 lbs (25 kg), making it a robust and efficient testing tool.

Cap manufacturers, breweries, and quality inspection agencies can greatly benefit from using the CCTT Tumbling Tester as it helps ensure the durability and quality of crown closures, ultimately leading to better product performance and customer satisfaction.

For assessing the durability of metal and coatings on crown caps by measuring wear through controlled tumbling tests.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.

Reviews

There are no reviews yet.