Click for full sized image

The CTC Cosmetic Tube Cutter offers an advanced solution for cutting plastic and metallic tubes with precision.

Designed for the cosmetic industry’s rigorous quality control needs, it ensures accurate and precise section cuts. With its easy operation and safety features, the CTC streamlines sample preparation for testing.

Cosmetic Tube Cutter CTC – Precision cuts for Quality Control:

Offering unparalleled precision and accuracy in cutting plastic and metallic tubes, the Cosmetic Tube Cutter CTC was developed specifically to meet the needs of the cosmetic industry. This instrument ensures replicable section cuts for quality control, making it a helpful tool for product development and production testing.

Characteristics:

Technical Specifications:

Optional Enhancements:

The Cosmetic Tube Cutter CTC is a unique lab tester that offers easy and accurate cuts for effective quality control. Its safety features and operational efficiency make it ideal for any cosmetic product testing lab.

The Cosmetic Tube Cutter CTC is designed for precise cutting of plastic and metallic tubes, specifically tailored to meet the quality control needs of the cosmetic industry. It ensures accurate and replicable section cuts for effective product development and testing.

The CTC Cosmetic Tube Cutter has compact dimensions of 275 x 210 x 375 mm and weighs 12 kg, making it easy to place and handle in any testing lab.

The Cosmetic Tube Cutter can accommodate tube samples with diameters ranging from 25 to 50 mm. Custom sizing options are also available upon request for specific needs.

The CTC is equipped with a durable metallic casing and an enclosed cutting chamber with a transparent plexiglass door to ensure operator safety. It also features a protective hinge design that prevents access during operation and a power-operated door for maximum safety.

Yes, the CTC Cosmetic Tube Cutter features a user-friendly operating system that allows for quick switching between different tube diameters, making it efficient and convenient for operators.

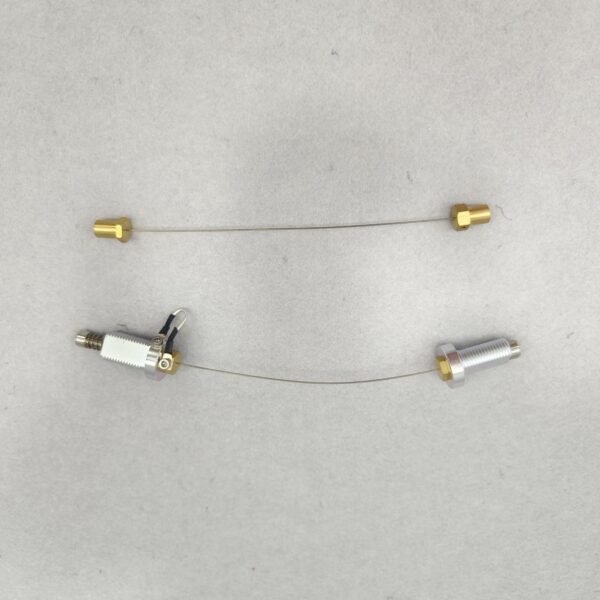

Optional enhancements include additional cutting sets for various sample diameters, providing added versatility for different cosmetic product testing needs.

The CTC Cosmetic Tube Cutter offers an advanced solution for cutting plastic and metallic tubes with precision.

Designed for the cosmetic industry’s rigorous quality control needs, it ensures accurate and precise section cuts. With its easy operation and safety features, the CTC streamlines sample preparation for testing.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.