Click for full sized image

A precision tool designed for cleanly sectioning PET bottles, ensuring accurate section weight analysis with minimal deformation, suitable for various bottle sizes and easy to operate with adjustable settings.

The HWBC-1 Hot Wire Cutter is designed for precise cutting of PET bottles, ensuring clean section cuts without deformation. This tool is particularly useful for accurate section weight analysis.

Efficient Cutting

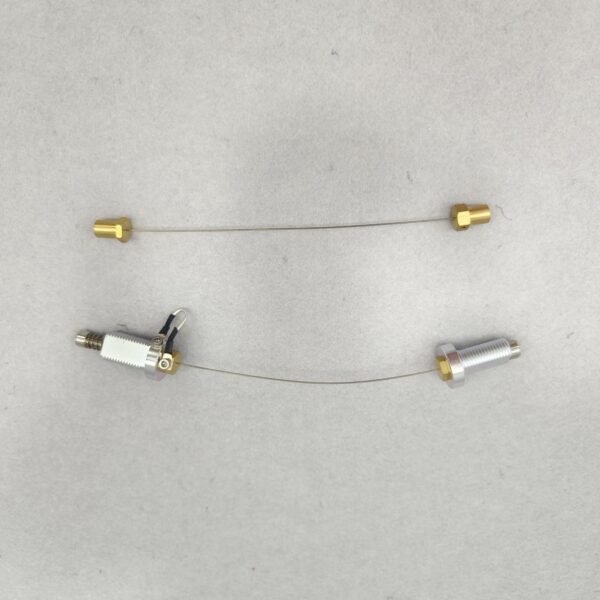

The HWBC-1 uses quick-heating wires to provide fast, efficient and consistent section cutting for reproducible section weight analysis.

User-Friendly Design

The cutter features an energy-efficient design with adjustable temperature settings. Its interface is simple, requiring minimal training to achieve accurate cuts. Adjustable supports allow for use with various bottle sizes, adding versatility.

Versatile Application

The HWBC-1 is suitable for bottle blowing analysis, capable of handling up to five sections per bottle to ensure compliance with section weight standards. It is available in both Standard and Large diameter versions to meet different industry requirements.

Key Features

Technical Specifications

The HWBC-1 Hot Wire Bottle Cutter is designed for precision section cutting of PET bottles, allowing for clean cuts that facilitate accurate section weight analysis. It is ideal for various applications in the packaging and beverage industries.

The HWBC-1 utilizes quick-heating wires that provide fast and efficient cutting. This technology minimizes deformation during the cutting process, ensuring that each section of the bottle is cut cleanly and accurately.

The HWBC-1 features adjustable temperature settings to accommodate different cutting needs and adjustable supports that allow it to work with various bottle sizes, enhancing its versatility for different applications.

The HWBC-1 is capable of cutting up to five sections from a single PET bottle, making it suitable for thorough bottle blowing analysis and compliance with section weight standards.

Yes, the HWBC-1 is designed for user-friendliness, requiring minimal training to operate. Its simple interface and clear instructions allow users to achieve accurate cuts quickly and efficiently.

The HWBC-1 has compatible finish sizes ranging from 0.7” to 1.5” (17 to 40 mm Ø), a maximum sample height of 16” (410 mm), and a maximum diameter of 5” (125 mm) for the standard model and 8.3” (210 mm) for the large model. It operates on a power supply of 115 or 220 VAC / 60Hz and has dimensions of 21” x 20.25” x 15.75” (535 x 515 x 400 mm) with a net weight of 44 lbs (20 kg).

A precision tool designed for cleanly sectioning PET bottles, ensuring accurate section weight analysis with minimal deformation, suitable for various bottle sizes and easy to operate with adjustable settings.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.

1 review for HWBC-1 Hot Wire Bottle Cutter for Precision Section Cutting of PET Bottles

njchurchill –

Best section cutter we’ve ever used.