Click for full sized image

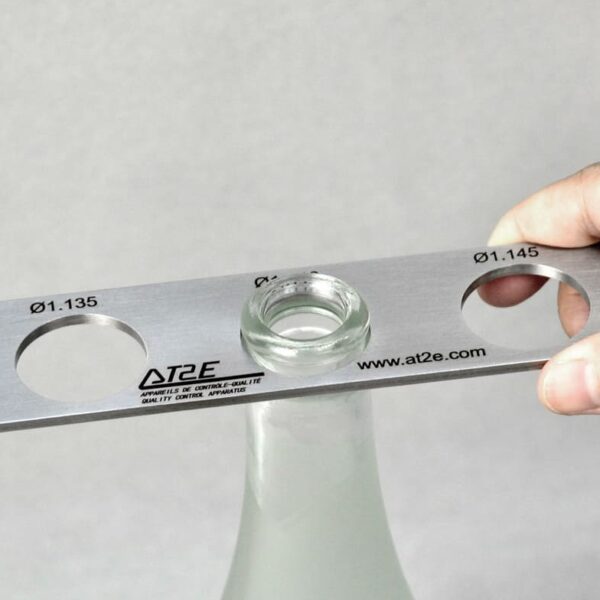

A precision tool designed to quickly and accurately verify whether a sample’s internal diameter falls within a specified range, ensuring compliance with preset standards.

The IDG-1 Internal Diameter Gauge is a precision tool designed to verify whether the internal diameter of a sample falls within a specified range. It ensures that the sample meets the required standards by providing a quick and accurate check.

This unit works by using two ends of the gauge: the smaller end should fit into the internal circle of the sample, confirming the minimum diameter, while the larger end should not fit, ensuring the maximum diameter is not exceeded.

The gauge is custom-made to specific diameter ranges, which customers must specify when placing an order.

The IDG-1 Internal Diameter Gauge is designed to quickly and accurately verify whether a sample’s internal diameter falls within a specified range, ensuring compliance with preset standards. It is essential for quality control in manufacturing and engineering processes.

The IDG-1 utilizes two ends: the smaller end fits into the internal circle of the sample to confirm the minimum diameter, while the larger end ensures that the maximum diameter is not exceeded. This dual approach allows for precise measurements.

Yes, the IDG-1 is custom-made to specific diameter ranges. Customers must specify their required diameter ranges when placing an order to ensure the gauge meets their measurement needs.

The IDG-1 is beneficial for various industries, including manufacturing, engineering, and quality control sectors, where precise internal diameter measurements are critical for product compliance and performance.

Yes, the IDG-1 is designed for ease of use, allowing operators to quickly verify internal diameters without complex procedures. Its straightforward design facilitates efficient measurements in both laboratory and field settings.

The advantages of using the IDG-1 include its precision, speed, and the ability to ensure compliance with industry standards. This tool enhances quality control processes and minimizes the risk of defects in manufactured products.

A precision tool designed to quickly and accurately verify whether a sample’s internal diameter falls within a specified range, ensuring compliance with preset standards.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.