Click for full sized image

An advanced, automated solution that delivers precise measurements of PET preforms and bottles, enhancing quality control in manufacturing with high accuracy and user-friendly design.

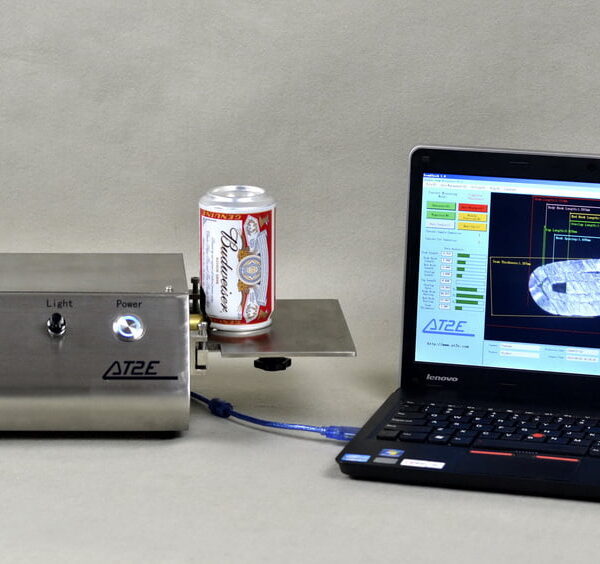

The PBMS Preform & Bottle Measuring System is designed to elevate precision and efficiency in quality control for bottle manufacturing. This advanced system uses cutting-edge optical multi-lens refraction technology to capture comprehensive contour images of PET preforms and bottles with unmatched accuracy.

Advanced Optical Technology

The PBMS utilizes segmented imaging and parallel lighting to capture precise contour images, achieving measurement accuracy up to 0.005mm. With sub-pixel processing, it is an essential tool for ensuring high-quality standards.

Automated Precision

The system is fully automated, measuring standard dimensions like neck and thread diameter, as well as detailed features such as flashing and concentricity. The bi-telecentric lens and intelligent auto-positioning enhance measurement reliability, making it indispensable for maintaining consistent product quality.

Modular and User-Friendly Design

The PBMS’s modular design allows for easy installation and operation, improving both accuracy and stability. The advanced software automatically selects the appropriate measurement modules and recognizes preform cavity numbers for efficient data recording.

The PBMS Preform & Bottle Measuring System is designed to provide precise measurements of PET preforms and bottles, enhancing quality control in the manufacturing process. It ensures that products meet high-quality standards through accurate dimensional analysis.

The PBMS utilizes advanced optical multi-lens refraction technology, segmented imaging, and parallel lighting to capture detailed contour images. This technology allows for measurement accuracy up to 0.005 mm, which is essential for maintaining product quality.

The PBMS can measure a variety of dimensions, including neck and thread diameter, wall thickness, inner diameter, and thread angle. It also assesses detailed features such as flashing and concentricity, providing comprehensive data for quality control.

Yes, the PBMS features a modular and user-friendly design with an intuitive 12″ touch screen interface. Its automated systems streamline the measurement process, making it simple for operators to install and use.

Yes, the PBMS supports comprehensive data storage and offers multiple interfaces for industrial setups, enabling easy data recording and access for further analysis.

The PBMS can be expanded with additional measuring systems and customizable finish spacers, allowing users to tailor the system to their specific measurement needs and enhance its functionality.

An advanced, automated solution that delivers precise measurements of PET preforms and bottles, enhancing quality control in manufacturing with high accuracy and user-friendly design.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.

Monday – Friday

06:00 AM – 06:00 PM

US Central Time

AT2E-USA Inc.

2835 N. Sheffield Ave.

Suite 237

Chicago IL 60657 USA