Click for full sized image

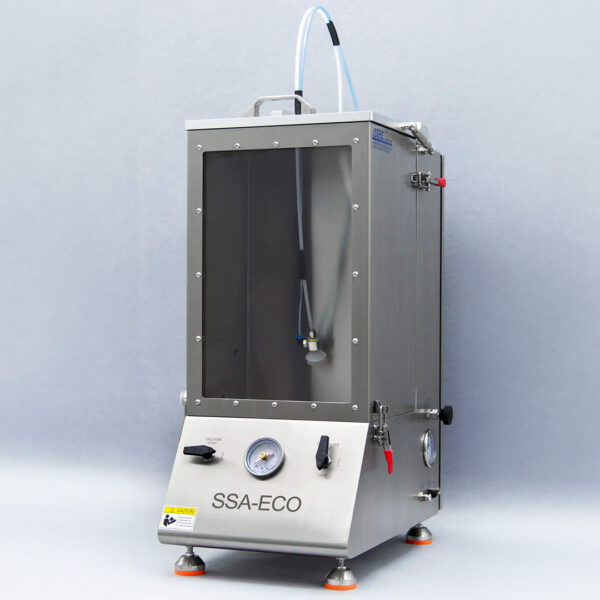

A high-precision device designed to evaluate the durability of PET bottles by simulating long-term stress conditions using sodium hydroxide solution, with multi-position testing, automated control, and robust safety features for accurate and reliable quality control.

The SCT-D Stress Crack Tester is a crucial tool for assessing the stress crack resistance of PET bottles. It simulates long-term conditions by exposing bottles to a sodium hydroxide solution, providing essential data for quality control purposes.

The SCT-D is available in models with 6 to 36 testing stations, allowing for efficient testing. Each station can be individually controlled, offering flexibility for various testing needs.

This tester operates within a pressure range of 0-6 Bar, with a display resolution of 0.01 Bar. The automated system ensures high accuracy and repeatability, delivering detailed data for each test.

The SCT-D is constructed with high-quality stainless steel and includes multiple safety features, such as a corrosion-resistant design and an anti-explosion observation window, ensuring a secure testing environment.

The SCT-D Stress Crack Tester is specifically designed to evaluate the durability of PET bottles by simulating long-term stress conditions through exposure to a sodium hydroxide solution. It is an essential tool for quality control in the packaging industry.

The SCT-D is available in models with varying numbers of testing stations, ranging from 6 to 36. This multi-position design allows for efficient and flexible testing, as each station can be controlled individually to meet different testing requirements.

The SCT-D operates with a test pressure accuracy of ± 0.5% F.S. and a display resolution of 0.01 Bar. This high level of accuracy ensures reliable and consistent results during testing.

The SCT-D is constructed with high-quality stainless steel and includes multiple safety features such as a corrosion-resistant design and an anti-explosion observation window. These features ensure a secure testing environment while monitoring the samples.

The SCT-D can accommodate PET bottles with diameters ranging from 60 to 120 mm and heights from 150 to 350 mm. For larger sample sizes, you can contact AT2E for compatibility options.

Yes, optional accessories for the SCT-D include a mini printer for data output and the “QualiCrack” professional software for enhanced data analysis and reporting capabilities.

A high-precision device designed to evaluate the durability of PET bottles by simulating long-term stress conditions using sodium hydroxide solution, with multi-position testing, automated control, and robust safety features for accurate and reliable quality control.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.