Click for full sized image

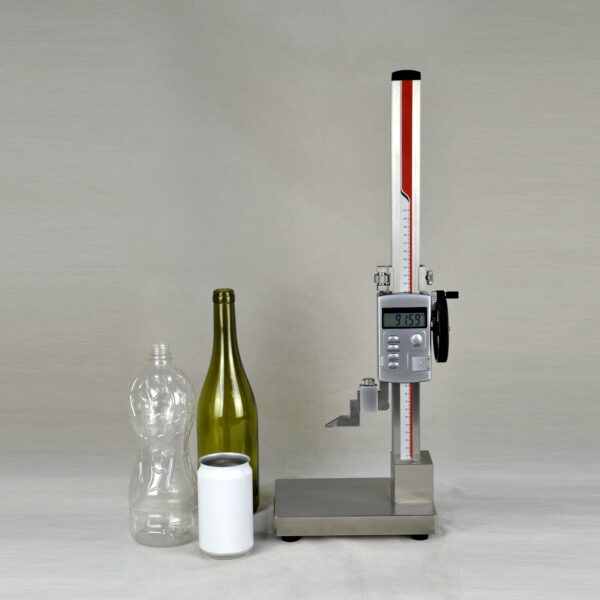

The SCT-ECO Stress Crack Tester measures the stress crack resistance of PET bottles, ensuring accurate and efficient quality control.

Models available:

SCT-ECO Stress Crack Tester for PET Bottle (Pneumatic Model)

The SCT-ECO Stress Crack Tester is essential for measuring the stress crack resistance of PET bottles. This device simulates long-term behavior by exposing bottles to sodium hydroxide solution, providing critical data for quality control. It has an ingenious design which allows it to operate just with compressed air, with no need of electrical power.

Attributes:

Technical specifications:

The SCT-ECO Stress Crack Tester is designed to measure the stress crack resistance of PET bottles, particularly those used for carbonated soft drinks. It simulates long-term exposure to stress by utilizing a sodium hydroxide solution, providing vital data for quality control in the manufacturing process.

The SCT-ECO operates using a pneumatic system, which means it requires only a compressed air supply to function. This makes it adaptable to various working environments and eliminates the need for electrical power, enhancing its usability in different settings.

The SCT-ECO is available in both single and double chamber models, with testing capacities ranging from 6 to 36 testing stations, allowing users to select the configuration that best meets their testing needs.

The SCT-ECO features a testing pressure range of 0 – 6 Bar with an accuracy of ± 0.5% F.S. It can accommodate bottles with a diameter of 60 – 125 mm and a height of 160 – 350 mm. The recommended operating temperature is between 5 – 50 °C, and it requires an air supply of 7 – 8 Bar.

Yes, the SCT-ECO is designed to test various sizes of PET bottles. The flexible position selection allows users to control each testing position manually, accommodating different bottle dimensions as needed.

The SCT-ECO incorporates various safety designs, including an anti-explosion feature and a clear observation window for easy monitoring of the sample status during testing. Its corrosion-resistant design also enhances durability and safety during operation.

The SCT-ECO Stress Crack Tester measures the stress crack resistance of PET bottles, ensuring accurate and efficient quality control.

Models available:

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.