Click for full sized image

A pneumatic, stainless steel device designed for thorough leak detection in 3-piece tinplate cans, offering 360° inspection and reliable results without the need for electricity. Ideal for maintaining high-quality standards in can manufacturing, it ensures precise and efficient testing.

The CLA-ECO Can Leak Analyzer is designed specifically for ensuring the integrity of empty 3-piece tinplate cans. With its water bath system and rotating can holders, it allows for a complete 360° inspection, ensuring that no potential leak goes unnoticed.

Key Features and Applications

The CLA-ECO Can Leak Analyzer is a vital tool for maintaining high-quality standards in can manufacturing, delivering accurate and reliable leak detection.

Technical Specifications

Test Procedure

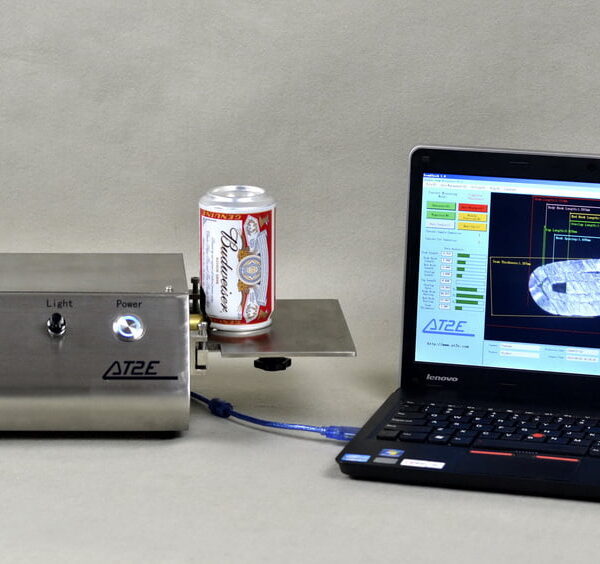

The CLA-ECO Can Leak Analyzer is designed for thorough leak detection in empty 3-piece tinplate cans. It performs a complete 360° inspection to ensure the integrity of the cans, focusing on critical areas like weld seams to identify any potential leaks.

The CLA-ECO operates using a pneumatic system without the need for electricity. It features a water bath system and rotating can holders, allowing for easy submersion and pressure application to detect leaks through the observation of air bubbles during testing.

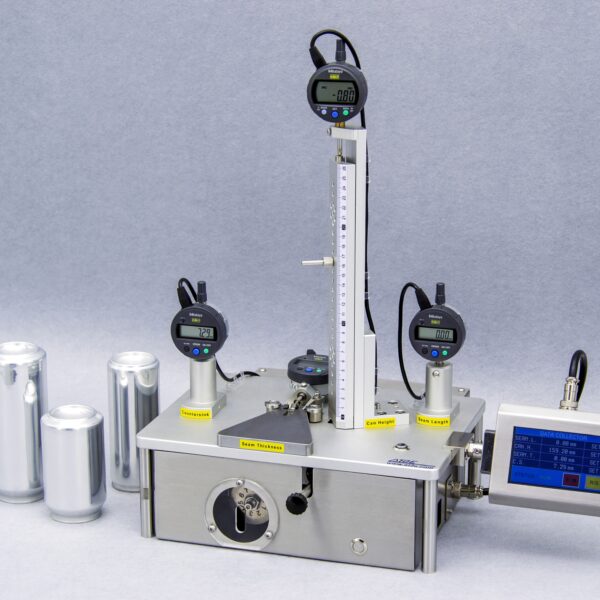

The CLA-ECO measures 910 x 650 x 825 mm (35.9 x 25.6 x 32.5 in) and has a net weight of 60 kg (132.3 lbs), making it a robust and durable tool for can leak detection.

The CLA-ECO has a pressure range of 0 – 6 bar (0 – 87 psi) with a resolution of 0.1 bar (1.45 psi), allowing for precise testing of can integrity.

Yes, the CLA-ECO is designed to accommodate various sizes of 3-piece tinplate cans, specifically those with a diameter ranging from 50 to 200 mm and a height of up to 240 mm, providing versatility in testing.

Absolutely! The CLA-ECO features a user-friendly design with manual valve controls that simplify the submersion and pressure application processes, making it easy for operators to conduct leak tests efficiently.

A pneumatic, stainless steel device designed for thorough leak detection in 3-piece tinplate cans, offering 360° inspection and reliable results without the need for electricity. Ideal for maintaining high-quality standards in can manufacturing, it ensures precise and efficient testing.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.