Click for full sized image

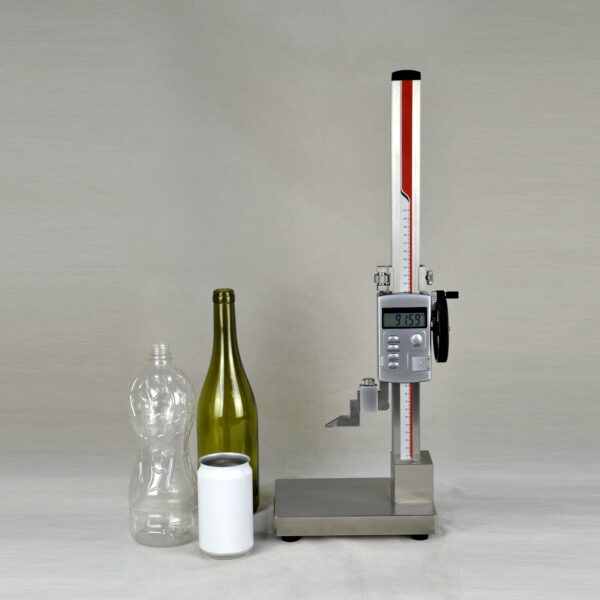

A dual-station device designed to efficiently test the internal pressure resistance of glass containers, offering precise, user-friendly operation and compliance with ISO 7458:2004 standards.

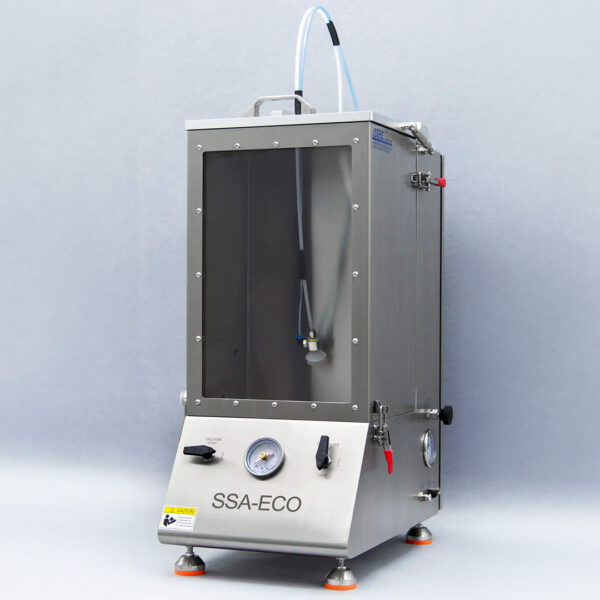

The GBBT-2 Glass Bottle Burst Tester is designed to test the internal pressure resistance of two glass containers at the same time. This tester is widely used by glass bottle manufacturers to ensure product quality and performance.

With a dual-station design, the GBBT-2 enables continuous testing, enhancing efficiency. The PLC-integrated touchscreen control allows users to easily set and monitor test cycles, ensuring precise pressure ramping and holding times.

The GBBT-2 features an automatic clamping and filling system, making operation and sample installation straightforward. Its stainless steel construction ensures long-lasting durability, while advanced safety features protect operators during testing.

Compliant with ISO 7458:2004 standards, the GBBT-2 delivers reliable and standardized test results. It offers real-time test curve reviews, data storage for multiple operators and products, and an RS232 output for data connectivity.

The pressure test can be performed up to a predefined pressure point (trial test) or until the sample breaks.

The GBBT-2 is engineered for efficient, reliable operation and easy maintenance, fully complying with ISO 7458:2004 standards.

The GBBT-2 Glass Bottle Burst Tester is designed to test the internal pressure resistance of glass containers. It is primarily used by glass bottle manufacturers to ensure product quality and performance, allowing for simultaneous testing of two bottles.

The dual-station design allows for continuous testing of two glass containers at the same time, significantly increasing the testing throughput. This feature is particularly beneficial for manufacturers looking to optimize their production processes and ensure quick quality assessments.

The GBBT-2 is equipped with advanced safety features, including a safety door that protects operators during testing. Additionally, its stainless steel construction and automatic clamping system enhance safety by minimizing the risk of accidents during operation.

Yes, the GBBT-2 has a data storage capability that allows it to save test results for multiple operators and products. This feature facilitates easy tracking of testing history and performance metrics, ensuring comprehensive quality control.

The GBBT-2 complies with ISO 7458:2004 standards, ensuring that it delivers reliable and standardized test results. This compliance is crucial for manufacturers who need to meet industry regulations and maintain high-quality production standards.

The GBBT-2 features an RS232 output, which allows for easy connection to printers or software for data management. This connectivity enables users to generate reports and analyze test data efficiently, streamlining the quality assurance process.

A dual-station device designed to efficiently test the internal pressure resistance of glass containers, offering precise, user-friendly operation and compliance with ISO 7458:2004 standards.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.

Reviews

There are no reviews yet.