Click for full sized image

For measurement of pop and tear forces of easy open ends, ensuring quality control in the can, food, and beverage industries. Its user-friendly interface, advanced data management, and versatile testing range make it an essential tool for reliable cap testing.

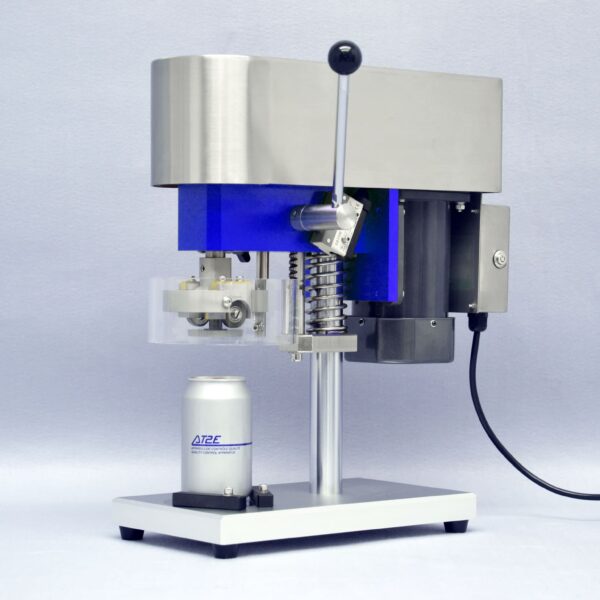

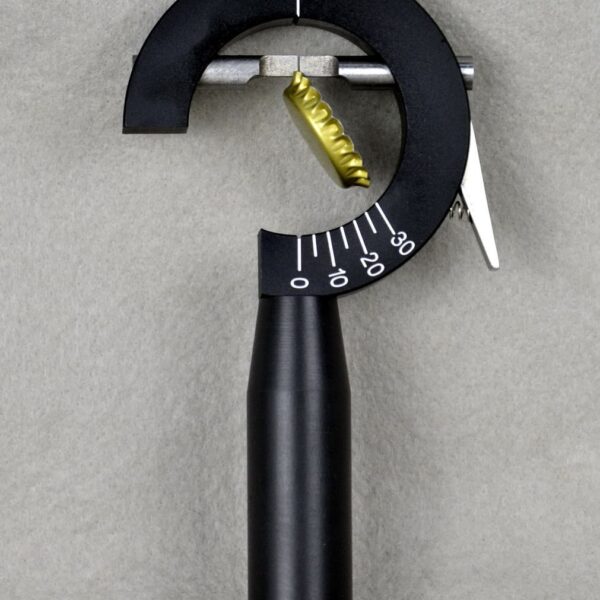

PATT-1 Pop and Tear Tester

The PATT-1 Pop and Tear Tester is designed for precise inspection of easy open ends in the can, food, and beverage industries. It accurately measures pop and tear forces to ensure high-quality standards.

Efficient Testing Process

Advanced Data Management

Versatile and Reliable

Technical Specifications:

The PATT-1 Pop and Tear Tester is designed to measure the pop and tear forces of easy open ends in the can, food, and beverage industries. It ensures quality control by providing accurate data on the performance of caps and lids.

The tester features a user-friendly interface with a high-definition touch screen. To operate, you simply install the end, hook the tab, and press start. The system automatically measures the pop and tear forces and displays the results in real-time on the screen.

The PATT-1 has a testing range of 0-100N with a resolution of 0.1N. It is capable of measuring forces in Newtons (N), kilograms-force (kgf), or pounds-force (lbf), making it versatile for different testing requirements.

The PATT-1 is applicable for a variety of sample types, including RPT, SOT, EO, OVAL, FSE, and APOE. This versatility makes it suitable for various easy open ends used in the packaging industry.

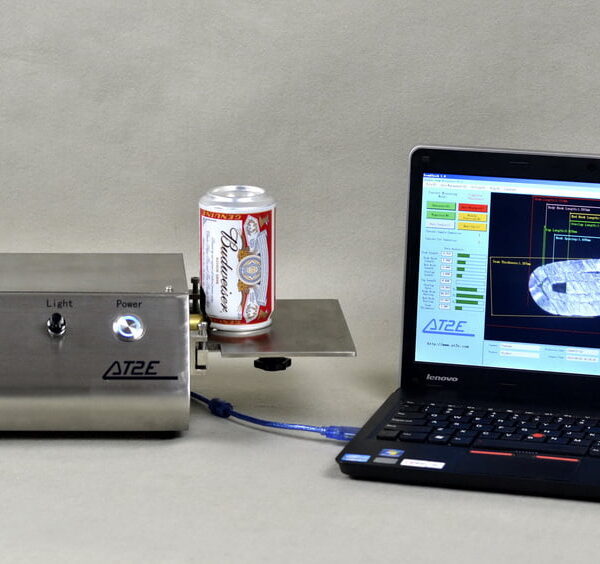

Yes, the PATT-1 utilizes professional software from AT2E for detailed data transfer and analysis. It includes an RS232 port for smooth data communication, allowing for accurate reporting and record-keeping.

The dimensions of the PATT-1 are 15.8″ x 19.3″ x 35.8″ (400 x 490 x 910 mm) and it weighs 120 lbs (55 kg), making it a robust and reliable piece of equipment for precise cap testing.

For measurement of pop and tear forces of easy open ends, ensuring quality control in the can, food, and beverage industries. Its user-friendly interface, advanced data management, and versatile testing range make it an essential tool for reliable cap testing.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.