Click for full sized image

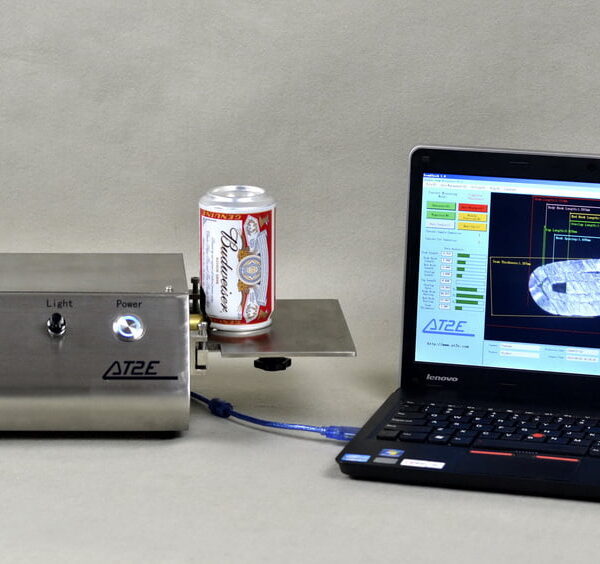

The PBMS X-Ray Preform & Bottle Measuring System is a precision tool designed for quality control in bottle manufacturing, using advanced computerized tomography to capture highly detailed images of PET preforms and bottles. It provides accurate measurements with resolutions as fine as 5 µm, ensuring reliable performance in a controlled environment.

PBMS X-Ray Preform & Bottle Measuring System

The PBMS X-Ray Preform & Bottle Measuring System is designed for quality control systems in bottle manufacturing. It uses computerized tomography to capture highly detailed images of PET preforms and bottles, ensuring accuracy in measurements as fine as 5 micrometers.

Technical Specifications:

General:

Cabinet:

Mechanics:

X-Ray Generator:

The PBMS X-Ray Preform and Bottle Measuring System is a precision tool utilized for quality control in the bottle manufacturing industry. It employs advanced computerized tomography to capture detailed images of PET preforms and bottles, ensuring accurate measurements and high-quality production standards.

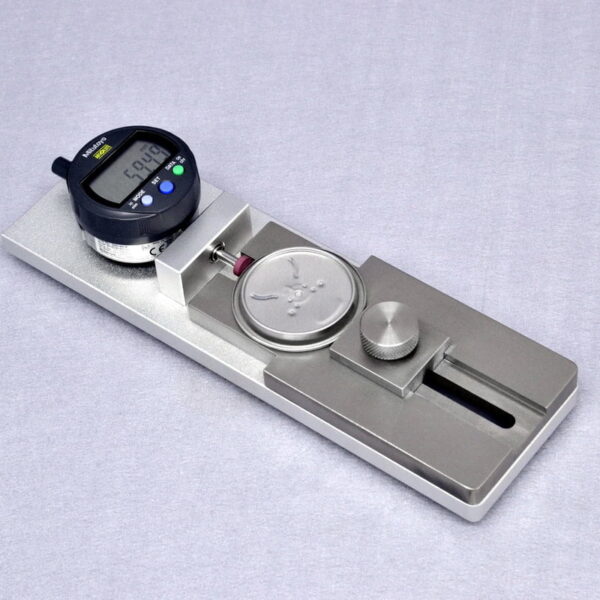

The PBMS X-Ray Measuring System offers a maximum resolution of approximately 5 µm per voxel for a 9 mm diameter sample and 10 µm per voxel for an 18 mm diameter sample. This high level of detail is crucial for ensuring precision in measurements during the manufacturing process.

The system is designed to operate in a controlled environment with an actively maintained temperature between +15°C to +25°C (59°F to 77°F) and a relative humidity of less than 80% (non-condensing). These conditions are essential for optimal performance and accuracy.

The outer dimensions of the PBMS X-Ray Measuring System are 1325 mm x 890 mm x 1865 mm (52.17 in x 35.04 in x 73.43 in), while the inner dimensions are 710 mm x 604 mm x 835 mm (27.95 in x 23.78 in x 32.87 in). The system weighs approximately 1020 kg (2249 lbs), making it a robust and substantial piece of equipment.

Yes, the PBMS X-Ray Measuring System is designed with safety in mind. It features a self-shielded cabinet with external radiation leakage of less than 0.5 µSv/h, ensuring that it can be operated safely in a controlled environment. Additionally, it has motorized sliding doors with large leaded windows for user access.

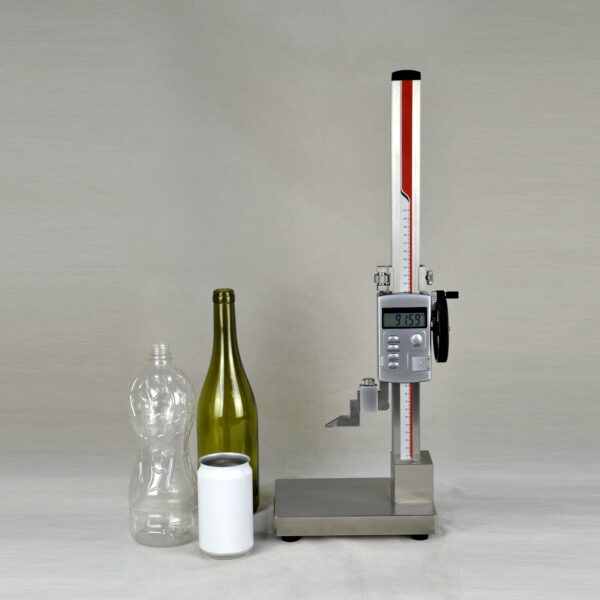

The system includes three precision granite-based linear motorized axes and one precision rotation stage, allowing for vertical travel of 275 mm, lateral travel of 195 mm, and magnification adjustment of 480 mm. It is capable of handling a maximum load of 5 kg on the rotation stage, providing versatility in measurement applications.

The PBMS X-Ray Preform & Bottle Measuring System is a precision tool designed for quality control in bottle manufacturing, using advanced computerized tomography to capture highly detailed images of PET preforms and bottles. It provides accurate measurements with resolutions as fine as 5 µm, ensuring reliable performance in a controlled environment.

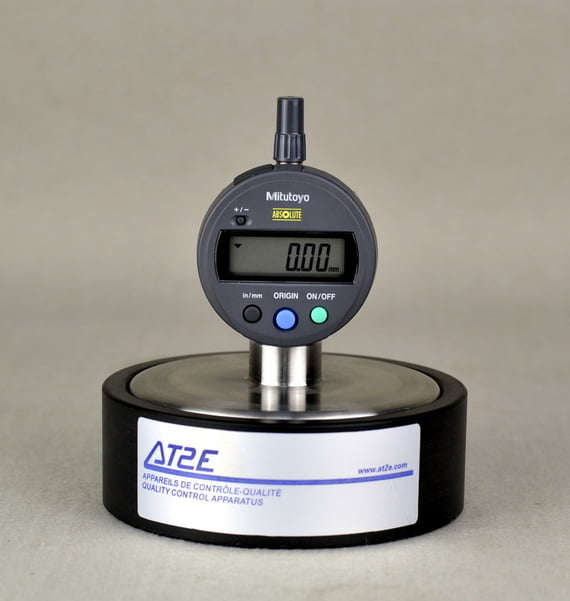

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.