Click for full sized image

A tool designed for cutting can seams and preparing them for accurate and reliable double seam inspections. It operates at 1450 rev/min, suitable for handling simple cutting tasks with clean results.

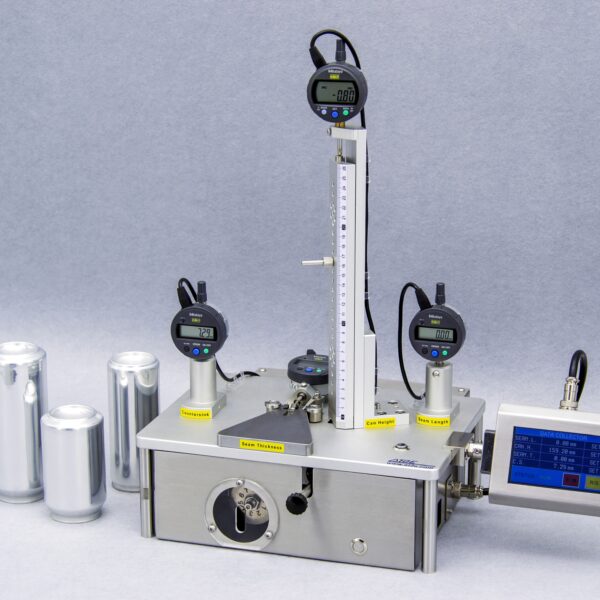

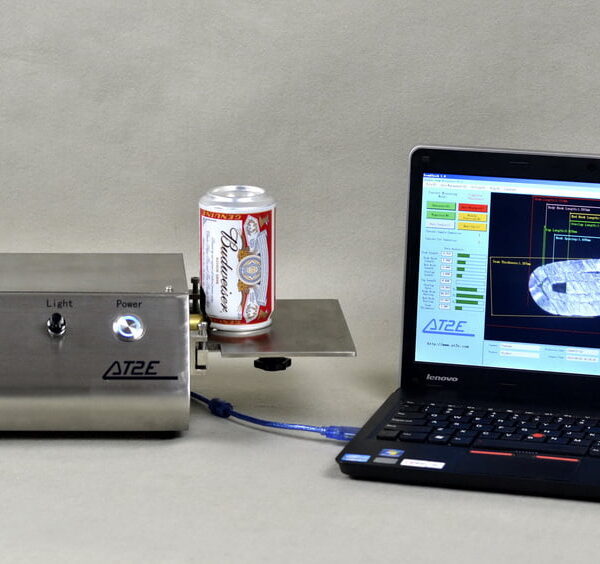

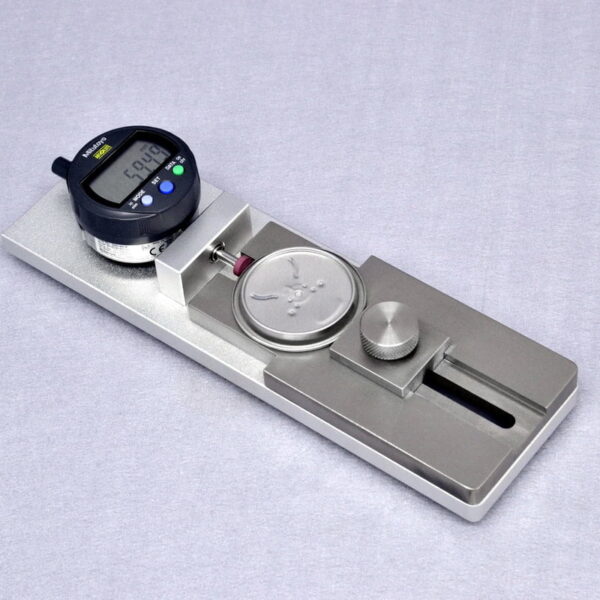

The ANSS – Antinoise Seaming Cutting Saw is designed for precise cutting of can seams, a critical step in double seam inspection. This saw operates at a speed of 1450 revolutions per minute (rev/min), making it suitable for simple cutting tasks while ensuring a clean seam section is obtained.

This clearer version ensures the purpose and specifications are easy to understand while providing both metric and imperial measurements.

The ANSS – Antinoise Seaming Cutting Saw is specifically designed for cutting can seams, which is crucial for conducting accurate and reliable double seam inspections. It ensures clean cuts, facilitating quality control in can manufacturing.

This cutting saw is compatible with both 2-piece and 3-piece cans, capable of handling can diameters of up to 65 mm (2.56 inches), making it versatile for various can types used in the industry.

The ANSS features a blade dimension of 80 x 22 x 0.5 mm (3.15 x 0.87 x 0.02 inches) with 160 teeth, operates at a motor speed of approximately 1450 rev/min, and works on a voltage of 220 V (other voltages available upon request). Its dimensions are 390 x 240 x 200 mm (15.35 x 9.45 x 7.87 inches), with a net weight of 15 kg (33 lbs).

Yes, an additional handle is available as an optional part, which can be used to accommodate different can sizes, enhancing the saw’s versatility and usability.

With its high-speed operation at 1450 rev/min and precision-engineered blade, the ANSS cutting saw is designed to provide clean and accurate cuts on can seams, which is essential for effective double seam inspections.

A tool designed for cutting can seams and preparing them for accurate and reliable double seam inspections. It operates at 1450 rev/min, suitable for handling simple cutting tasks with clean results.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.

Monday – Friday

06:00 AM – 06:00 PM

US Central Time

AT2E-USA Inc.

2835 N. Sheffield Ave.

Suite 237

Chicago IL 60657 USA

Reviews

There are no reviews yet.