Click for full sized image

A durable, electric-free device designed to efficiently test the internal pressure resistance of PET bottles up to 3.3 liters, ensuring container safety and quality across various environments.

PBBT-ECO PET Bottle Burst Tester

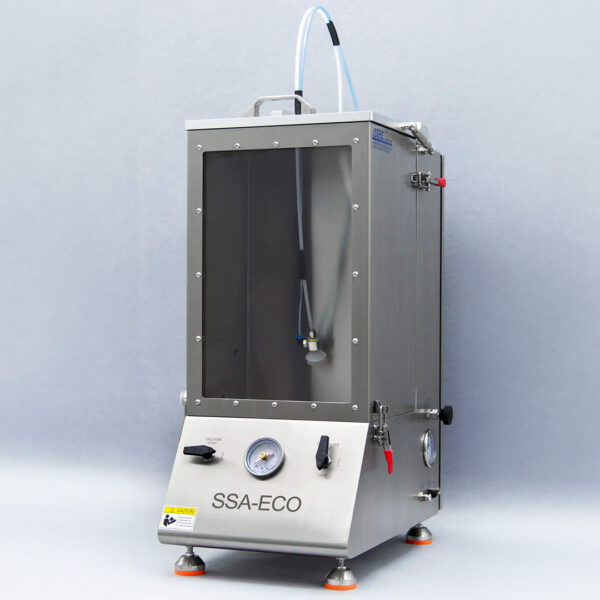

The PBBT-ECO is specialized equipment designed to test the internal pressure resistance of PET bottles. It features rapid pressurization and high-pressure testing capabilities, ensuring the durability and safety of PET containers.

The PBBT-ECO operates without electricity, making it versatile and suitable for various environments. It is capable of testing bottles up to 3.3 liters in size, with optional boosters available for higher pressure requirements. The adjustable ramp pressure and compatible clamping system improve the testing process.

Constructed from stainless steel, the PBBT-ECO is durable and easy to maintain. Its user-friendly design ensures simple operation, with built-in safety features to protect operators during testing.

The PBBT-ECO PET Bottle Burst Tester is designed to efficiently test the internal pressure resistance of PET bottles, ensuring their safety and quality by determining their durability under pressure.

The PBBT-ECO operates using a manual pressurization system, making it versatile for use in various environments where electricity may not be available. This feature allows for efficient testing without the need for electrical components.

The PBBT-ECO can test PET bottles up to 3.3 liters in size. For larger bottles, it is recommended to consult with the manufacturer for compatibility and testing capabilities.

The PBBT-ECO has a measuring range of 0-20 bar (0-300 psi) with a resolution of 0.5 bar / 5 psi. It operates within a temperature range of 4 to 50°C (40 to 122°F) and has dimensions of 510 (L) × 720 (W) × 990 (H) mm, weighing 85 kg.

Yes, optional components include an additional pressure booster for higher pressure testing, a compatible clamping system for better bottle stability, and a precision pressure gauge for calibration purposes.

The PBBT-ECO is designed with built-in safety features that protect operators during testing, ensuring a safe working environment while conducting pressure tests on PET bottles.

A durable, electric-free device designed to efficiently test the internal pressure resistance of PET bottles up to 3.3 liters, ensuring container safety and quality across various environments.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.

Monday – Friday

06:00 AM – 06:00 PM

US Central Time

AT2E-USA Inc.

2835 N. Sheffield Ave.

Suite 237

Chicago IL 60657 USA