Click for full sized image

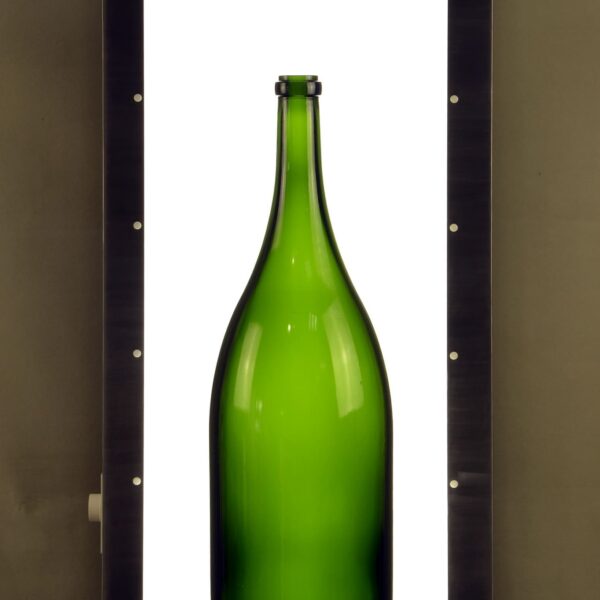

A fully automated system designed for precise testing of glass containers’ internal pressure resistance, featuring customizable test cycles, durable stainless steel construction, and advanced safety features. It automatically sends data to a connected acquisition system.

The GBBT-AUTO is designed to test the internal pressure resistance of glass containers. It features a fully automated control system, eliminating the need for operator intervention during testing. Data is automatically sent to the acquisition system, enhancing both efficiency and accuracy.

This tester offers customizable pressure ramping rates and can accommodate up to 16 pre-stored test cycles. Users can quickly select the appropriate cycle for different products without needing to adjust settings, ensuring flexible and efficient testing.

The GBBT-AUTO is equipped with a touchscreen interface for easy operation. Its stainless steel construction ensures durability, while advanced safety features protect the operator. The device can store data for up to 10 operators and 30 products, making it ideal for maintaining and improving product quality.

The GBBT-AUTO can perform pressure tests up to a predefined point (pass test) or until the container fails or reaches the maximum test pressure. It allows for up to 4 customizable test steps, including pressure levels and holding times, making it adaptable to various testing requirements.

For other ranges and specifications, please consult AT2E.

The GBBT-AUTO is designed to test the internal pressure resistance of glass containers. It ensures that bottles can withstand the required pressure levels during filling and storage, which is crucial for quality assurance in the beverage and packaging industries.

The GBBT-AUTO features a fully automated control system that eliminates the need for operator intervention during testing. It allows for customizable pressure ramping rates and can store up to 16 pre-stored test cycles, enabling quick selection and efficient testing of different products.

The GBBT-AUTO has a measuring range of 0-60 bar (0-870 psi) with a resolution of 0.1 bar (1.45 psi). It operates on a power supply of 220 V / 50Hz and requires an air supply of 6-8 bar (87-116 psi). The device can accommodate containers with neck dimensions between 25-33 mm and has a sample capacity of up to 3.5 L (118.4 fl oz).

Yes, the GBBT-AUTO is equipped with advanced safety features, including an operator protection door and overload protection. These features ensure a safe testing environment while maintaining high testing standards.

Yes, the GBBT-AUTO can store data for up to 10 operators and 30 different products. This capability aids in maintaining comprehensive records and improving product quality over time.

The GBBT-AUTO automatically sends testing data to a connected data acquisition system, enhancing accuracy and reliability. This feature allows for real-time monitoring and analysis of test results.

A fully automated system designed for precise testing of glass containers’ internal pressure resistance, featuring customizable test cycles, durable stainless steel construction, and advanced safety features. It automatically sends data to a connected acquisition system.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.

Monday – Friday

06:00 AM – 06:00 PM

US Central Time

AT2E-USA Inc.

2835 N. Sheffield Ave.

Suite 237

Chicago IL 60657 USA