Click for full sized image

A precision tool designed for accurate seam cutting of 2-piece, 3-piece, and aerosol aluminum cans, featuring a linear guide rail for repeatable cuts and a high-speed motor to ensure reliable seam inspections. Durable and easy to maintain, it’s an essential tool for quality control of cans.

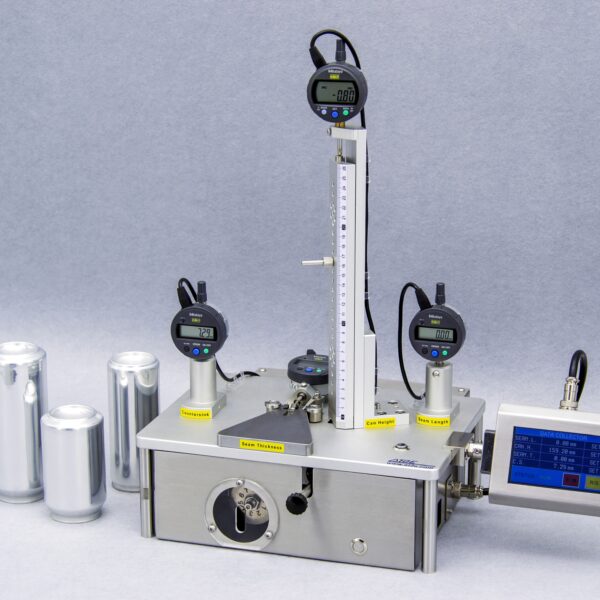

The SS-1 Seaming Cutting Saw is specifically designed for precise seam cutting of aluminum cans, ensuring accurate inspection results. Featuring a linear guide rail, it delivers precise and repeatable cuts for 2-piece, 3-piece, and aerosol cans.

The linear guide rail provides exact movement, resulting in a clearer seam section compared to standard seam saws. This improves the quality and reliability of seam inspections.

The SS-1 is suitable for various can types, including 2-piece, 3-piece, and aerosol cans with diameters up to 180 mm. It is equipped with a high-speed motor operating at approximately 1000 RPM.

Built with high-quality materials, the SS-1 is durable and easy to maintain. Its design facilitates easy collection of cutting debris, helping to keep the workspace clean.

The SS-1 Seaming Cutting Saw is an essential tool for quality control in can manufacturing, providing precise and reliable seam inspections.

The SS-1 Seaming Cutting Saw is designed for precise seam cutting of aluminum cans, including 2-piece, 3-piece, and aerosol types. It ensures accurate seam inspections, making it an essential tool for quality control in can manufacturing.

The linear guide rail of the SS-1 provides exact movement, allowing for more precise and repeatable cuts compared to standard seam saws. This results in clearer seam sections, enhancing the quality and reliability of seam inspections.

The SS-1 is versatile and can accommodate various can types, specifically 2-piece, 3-piece, and aerosol cans with diameters up to 180 mm, making it suitable for a wide range of applications in the can manufacturing industry.

The SS-1 features a blade dimension of 80 x 22 x 0.5 mm with 160 teeth, a motor speed of approximately 1000 RPM, and operates on a working voltage of 220 V. Its dimensions are 240(L) x 335(W) x 170(H) mm, and it has a net weight of 20 kg.

Yes, the SS-1 is built with high-quality materials that ensure durability and easy maintenance. Its design also facilitates the easy collection of cutting debris, helping to keep the workspace clean and organized.

The SS-1 Seaming Cutting Saw enhances quality control by providing precise and reliable seam inspections, which are crucial for ensuring the integrity and safety of aluminum cans. Its accurate cutting capabilities help identify any potential defects in the seams, contributing to overall product quality.

A precision tool designed for accurate seam cutting of 2-piece, 3-piece, and aerosol aluminum cans, featuring a linear guide rail for repeatable cuts and a high-speed motor to ensure reliable seam inspections. Durable and easy to maintain, it’s an essential tool for quality control of cans.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.