Click for full sized image

Designed to verify the air-tightness of bottle crown caps, ensuring product integrity by detecting any leaks through a straightforward pressure testing process. It is widely used in the beverage and bottle cap manufacturing industries.

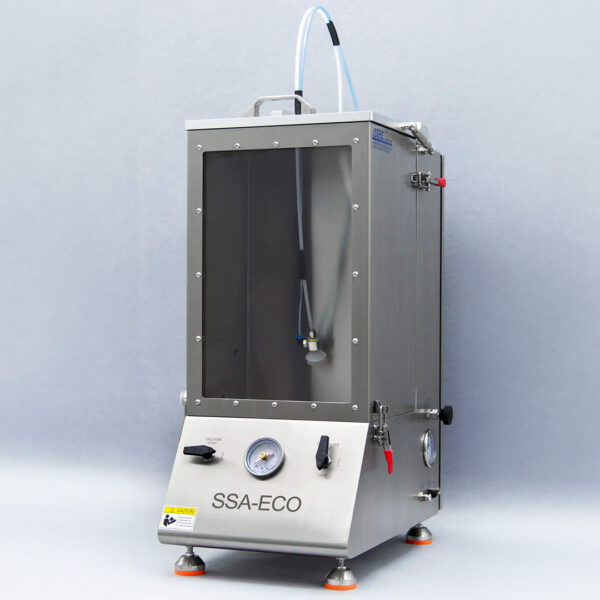

The Crown Cap Leak Tester is specifically designed to efficiently assess the air-tightness of bottle crown caps. Constructed from robust stainless steel, this tester offers long-lasting durability and reliable performance, making it an essential tool for breweries and bottling lines.

Key Features and Applications

Widely used in the beverage and bottle cap manufacturing industries, this tester ensures product integrity and customer satisfaction through rigorous testing.

Technical Specifications Summary

The CCLT Crown Cap Leak Tester is designed to verify the air-tightness of bottle crown caps. It ensures product integrity by detecting any leaks through a straightforward pressure testing process, making it essential for breweries and bottling lines.

To use the CCLT, simply place the crown cap on the bottle neck, submerge it in the water tank, and increase the internal pressure. If there are any leaks, bubble formation will indicate the presence of air escaping, allowing for quick and effective testing.

The CCLT has a pressure range of up to 12 bar (174 PSI) and can utilize nitrogen (N₂), carbon dioxide (CO₂), or compressed air as the pressure source. Its dimensions are 250 x 200 x 300 mm (9.8 x 7.9 x 11.8 in), and it weighs 3 kg (6.6 lbs.), making it compact and lightweight for easy integration into quality control processes.

Yes, the CCLT is specifically designed for testing crown caps, making it versatile for use in various beverage and bottle cap manufacturing applications. It ensures that different types of crown caps maintain their seal integrity.

The CCLT is widely used in the beverage industry, particularly in breweries and bottling lines, as well as in bottle cap manufacturing industries, to ensure the quality and safety of bottled products.

The CCLT is constructed from robust stainless steel, providing long-lasting durability and reliable performance, which is essential for rigorous testing in industrial environments.

Designed to verify the air-tightness of bottle crown caps, ensuring product integrity by detecting any leaks through a straightforward pressure testing process. It is widely used in the beverage and bottle cap manufacturing industries.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.

Reviews

There are no reviews yet.