Click for full sized image

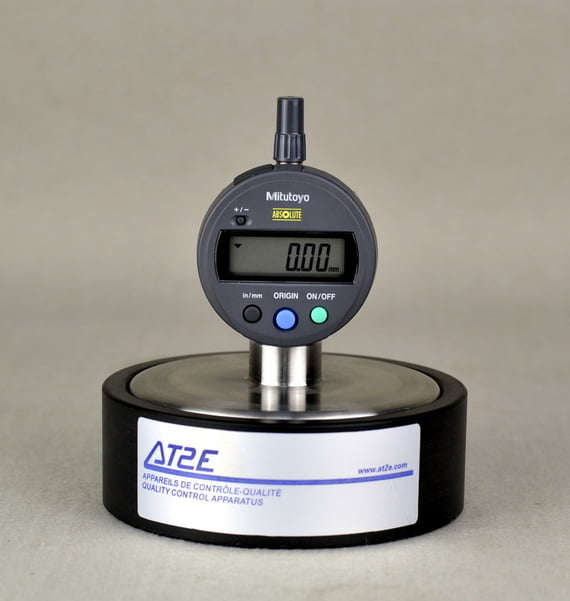

A precise tool designed to verify the centricity of the injection point in blown bottles, ensuring accurate quality control in manufacturing. It features an adjustable centering clamp and an easy-to-read scale for quick and efficient operation.

GCG Gate Center Gauge

Ensure the precise centricity of the injection point in blown bottles with the GCG Gate Center Gauge. This essential tool supports quality control in bottle manufacturing.

Accurate Centricity Verification

The GCG Gate Center Gauge provides precise measurements of the injection point’s centricity in blown bottles, ensuring that the injection point is accurately centered to enhance product quality.

Easy to Use

Featuring an adjustable centering clamp and an easy-to-read scale, the GCG Gauge simplifies the process of verifying bottle centricity. Its user-friendly design allows for quick and efficient operation.

Versatile and Durable

Designed to accommodate bottles up to 85 mm in diameter, the GCG Gauge is suitable for a wide range of bottle types. Its robust construction ensures long-lasting durability.

The GCG Gate Center Gauge enables quick and easy verification of the injection point centricity in blown bottles. The adjustable centering clamp and easy-to-read scale make the operation simple and efficient.

Technical Specifications:

The GCG Gate Center Gauge is designed to verify the centricity of the injection point in blown bottles, ensuring accurate quality control during the manufacturing process. It helps maintain product quality by confirming that the injection point is precisely centered.

The gauge features an adjustable centering clamp that securely holds the bottle in place. Users can then utilize the easy-to-read scale to quickly measure and verify the centricity of the injection point, making the process efficient and straightforward.

The GCG Gate Center Gauge can accommodate bottles with a diameter of up to 85 mm (3.35 in). For larger diameters, it is recommended to consult AT2E for suitable solutions.

Yes, the GCG Gate Center Gauge is designed with user-friendliness in mind. Its adjustable centering clamp and clearly marked scale allow for quick and efficient operation, making it accessible for operators in the manufacturing setting.

The GCG Gate Center Gauge has a weight of 4 kg (8.82 lbs) and is specifically designed for bottles with a diameter of up to 85 mm. Its robust construction ensures durability and reliability in various manufacturing environments.

Yes, the GCG Gate Center Gauge is versatile and suitable for a wide range of bottle types, making it an essential tool in quality control for blown bottle manufacturing.

A precise tool designed to verify the centricity of the injection point in blown bottles, ensuring accurate quality control in manufacturing. It features an adjustable centering clamp and an easy-to-read scale for quick and efficient operation.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.