Click for full sized image

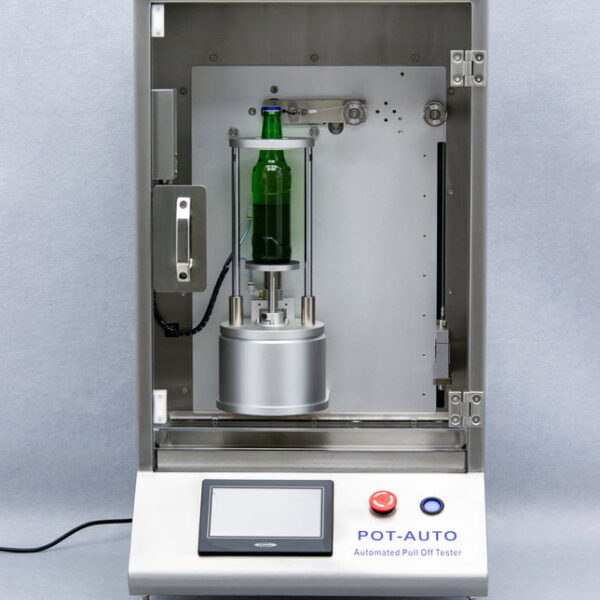

An automated device designed for precise compression and traction testing of packaging materials, offering durable construction, and user-friendly operation, made for versatile applications across industries such as cosmetics, pharmaceuticals, and packaging.

The FT-1 Fatigue Tester ensures the durability and quality of packaging through automated compression and traction tests, delivering reliable data for quality assurance.

Comprehensive Testing

The FT-1 performs automated top-load pressure and traction tests with precision. Its digital display shows real-time, peak, or average force values, providing accurate results for various packaging materials.

Durable and User-Friendly Design

Constructed from full stainless steel and equipped with a safety door, the FT-1 is both durable and safe. The 4.3-inch LCD touchscreen interface enhances user-friendliness, making operation straightforward.

Versatile Applications

The FT-1 is ideal for the cosmetic, pharmaceutical, and packaging industries. It supports both manual and automatic cylinder movements and comes with data collection software, simplifying force value management and analysis.

Key Advantages:

Technical Specifications:

Optional Accessories:

The FT-1 Fatigue Tester is designed for precise compression and traction testing of packaging materials. It ensures the durability and quality of packaging, making it ideal for industries such as cosmetics, pharmaceuticals, and general packaging.

The FT-1 can perform automated top-load pressure tests and traction tests. It has modes for both compression and traction (push and pull) testing, providing reliable data for quality assurance.

The FT-1 features a digital display that shows real-time, peak, or average force values. This allows users to easily monitor and analyze the results during testing.

Key features of the FT-1 include a full stainless steel construction, a safety door for enhanced safety, a 4.3-inch LCD touchscreen for easy operation, customizable sample ranges for compression and traction tests, and data collection software for managing force values.

The FT-1 can accommodate a maximum sample height of up to 200 mm (7.9 inches) for compression tests and up to 120 mm (4.7 inches) for traction tests, with customizable options available upon request.

Yes, the FT-1 comes with data collection software that simplifies the management and analysis of force values, allowing users to efficiently handle and interpret testing data.

An automated device designed for precise compression and traction testing of packaging materials, offering durable construction, and user-friendly operation, made for versatile applications across industries such as cosmetics, pharmaceuticals, and packaging.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.

Monday – Friday

06:00 AM – 06:00 PM

US Central Time

AT2E-USA Inc.

2835 N. Sheffield Ave.

Suite 237

Chicago IL 60657 USA