Click for full sized image

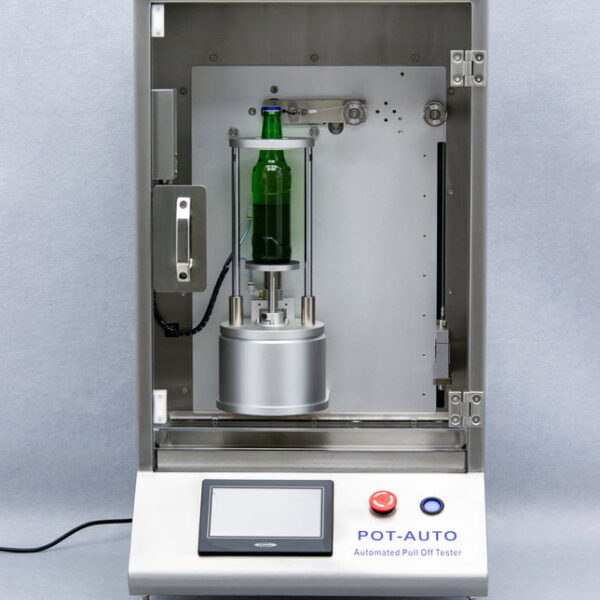

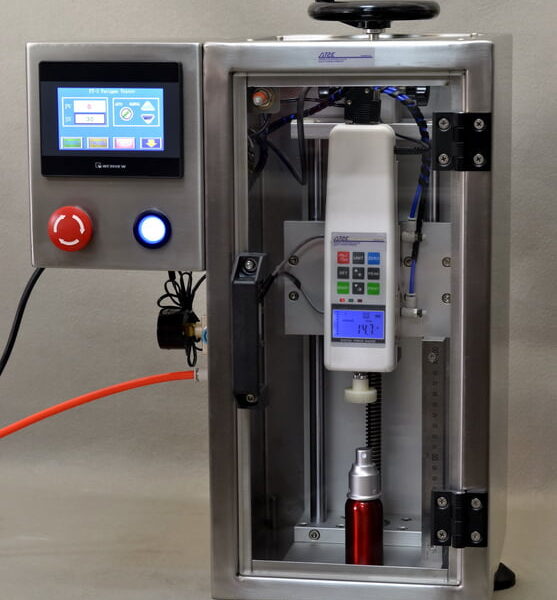

AT2E’s PLS Production Line Simulator allows to simulate in a reproducible and accelerated way the friction on a packaging line.

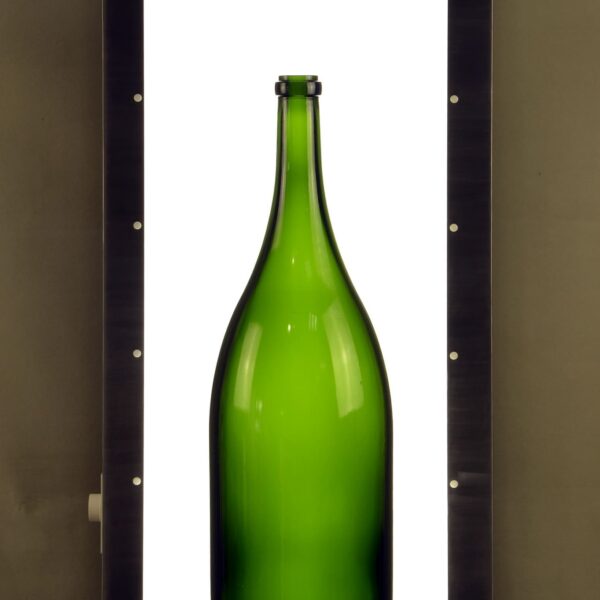

The testing process simulates the abrasions associated with contacts between bottles, typical of packaging lines.

This device is ideal for determining the build quality of glass bottles as well as their coatings, decorations and labeling.

Applications :

Characteristics

Technical specifications :

AT2E’s PLS Production Line Simulator allows to simulate in a reproducible and accelerated way the friction on a packaging line.

The testing process simulates the abrasions associated with contacts between bottles, typical of packaging lines.

This device is ideal for determining the build quality of glass bottles as well as their coatings, decorations and labeling.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.

Monday – Friday

06:00 AM – 06:00 PM

US Central Time

AT2E-USA Inc.

2835 N. Sheffield Ave.

Suite 237

Chicago IL 60657 USA