Precise Swing Top Stopper Testing

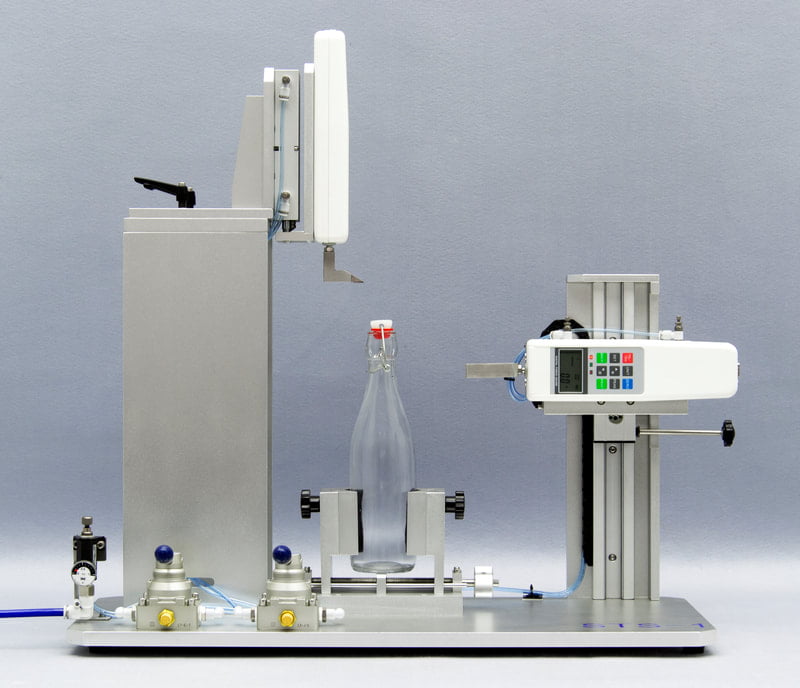

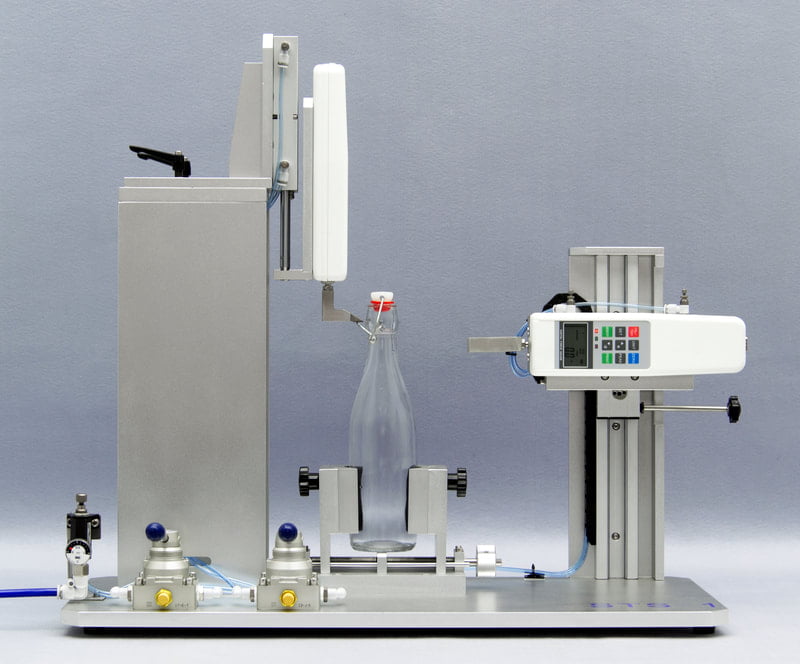

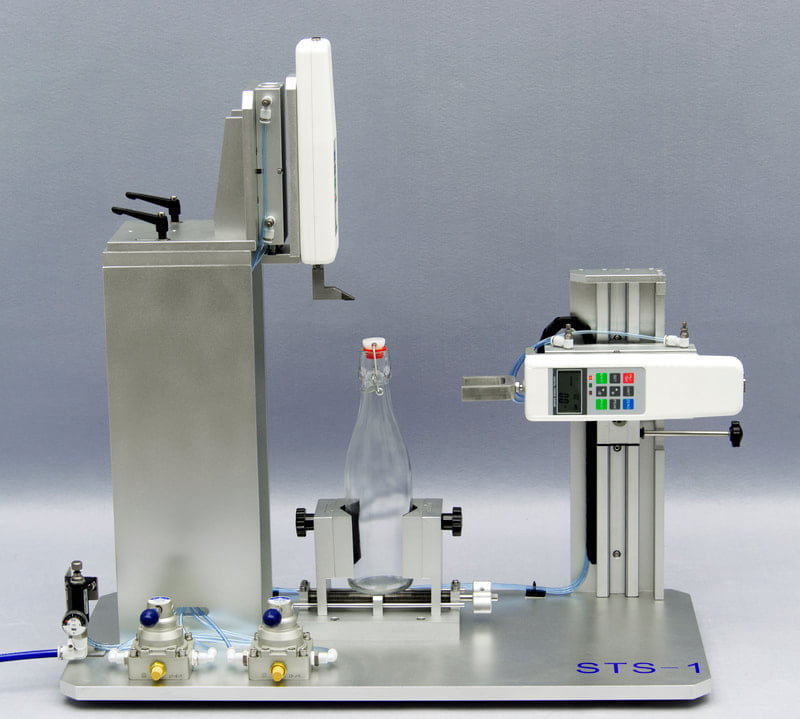

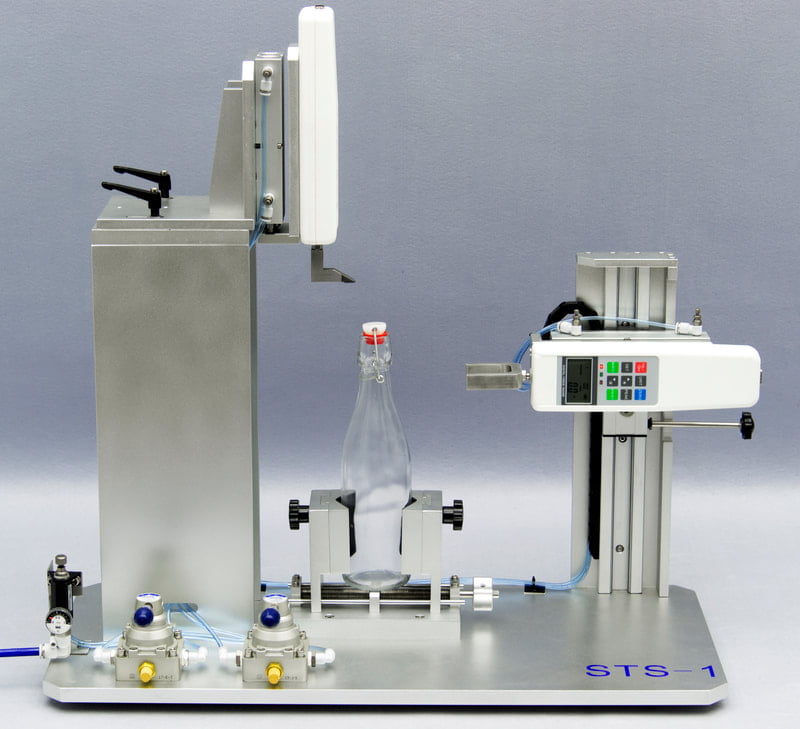

The STS-1 Swing Top Stopper Tester is designed to precisely measure the opening and closing forces of swing top stoppers on bottles. This innovative device features two dynamometers for accurate force measurement and a semi-automatic operation cycle for ease of use. Its adjustable testing position allows for compatibility with various bottle heights, ensuring versatility.

Key Features

- High Accuracy: Equipped with built-in dynamometers for precise measurements.

- User-Friendly: Semi-automatic operation simplifies the testing process.

- Versatile: Adjustable to accommodate bottles of different heights.

How It Works

The STS-1 operates by clamping the bottle, adjusting the stopper position, and utilizing pneumatic valves to measure the opening and closing forces at stable speeds. The dynamometers provide accurate force readings, making the STS-1 an essential tool for quality control.

Technical Specifications

- Force Ranges: 0-50 N, 0-100 N, or 0-200 N (Please specify when ordering)

- Digital Displays: Includes options for recalibration and multiple measurement modes.

- Compact and Durable: Designed for reliable performance in various testing environments.

Features

- Easy to use

- High repeatability in testing

- Built-in dynamometer with software integration

Testing Procedure

- Install the bottle into the clamp and adjust the swing top stopper position, then secure the clamp.

- Move the pneumatic valve to the testing position for the opening force test. The system will test at a stable speed, and the dynamometer will measure the force. Once the test is complete, return the valve to the standby position.

- Repeat the process for the closing force test, using the corresponding pneumatic valve. Once the test is done, return the valve to the standby position.

Dynamometer Specifications

- Range Options: 0-50 N, 0-100 N, 0-200 N

- Measurement Capabilities: Measures tensile and compressive strain

- Display: Digital, with reversible display options

- Measurement Modes: Continuous, Peak, PC Link

- Accuracy: 0.01 N (0-50 N), 0.05 N (0-100 N), 0.1 N (0-200 N)

- Units: kgf, Lbf, N

- Battery: Integrated, with charge status display

- Data Transfer: Curve data transfer to software

Mechanical Specifications

- Air Supply: 0-6 bar (0-87 psi)

- Dimensions: 700 x 350 x 650 mm (27.56 x 13.78 x 25.59 in)

- Weight: 21 kg (46.3 lbs.)