Click for full sized image

Provides precise measurements of plate thickness in can manufacturing, featuring a user-friendly design and compatibility with SPC systems for seamless data transfer, ensuring reliable quality control.

Accurate Measurements

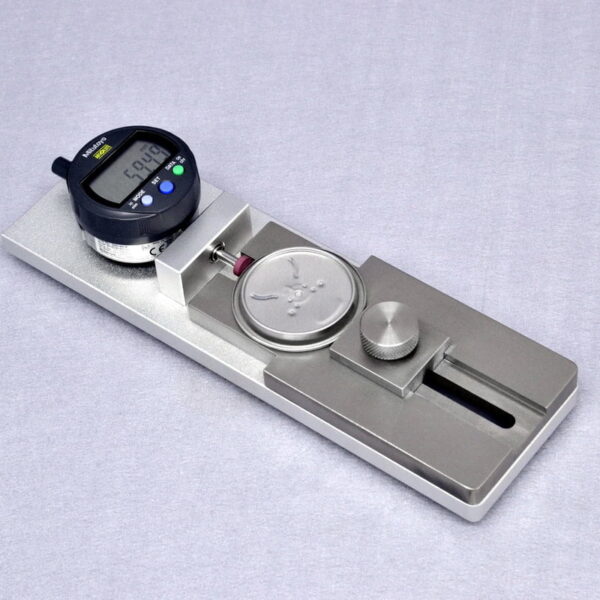

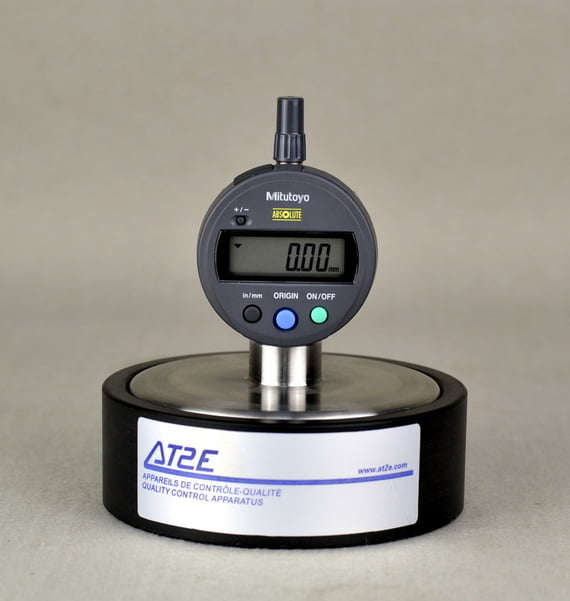

The PTG-1 measures plate thickness within a range of 0-10 mm, with a resolution of 0.001 mm and an accuracy of ±0.003 mm. This high level of precision is crucial for maintaining quality standards in production.

User-Friendly Design

The PTG-1 is designed for ease of use, reducing the risk of manual recording errors. It can be connected to an SPC system or AT2E’s SeamCheck software via the DTB-1 Data Transporting Box, enabling seamless data transfer.

Durable and Compact

The PTG-1 is compact and built to withstand the rigors of industrial use, ensuring consistent performance and reliability across various production environments.

In summary, the PTG-1 Can Plate Thickness Gauge is essential for ensuring accurate thickness measurements and supporting consistent quality control in can manufacturing.

Technical Specifications:

The gauge can be connected to an SPC system or AT2E’s SeamCheck software via the DTB-1 Data Transporting Box and cable, allowing for automated data transfer and reducing the potential for manual errors.

The PTG-1 Can Plate Thickness Gauge is specifically designed for precise measurement of plate thickness in can manufacturing. It plays a crucial role in quality control by ensuring that the thickness of the plates meets production standards.

The PTG-1 has a measuring range of 0-10 mm, with a resolution of 0.001 mm and an accuracy of ±0.003 mm. This high precision is essential for maintaining quality standards in can production.

The PTG-1 can be connected to an SPC system or AT2E’s SeamCheck software through the DTB-1 Data Transporting Box. This feature allows for seamless data transfer, reducing the risk of manual recording errors.

Yes, the PTG-1 is designed with a user-friendly interface that minimizes the risk of manual errors during operation. Its compact design also makes it easy to handle in various production environments.

The PTG-1 measures 192 mm in length, 100 mm in width, and 95 mm in height, with a net weight of 1 kg. Its compact size makes it suitable for use in tight spaces within manufacturing facilities.

The PTG-1 is built to withstand the rigors of industrial use, ensuring consistent performance and reliability across various production environments. Its durable construction makes it an essential tool for quality control in can manufacturing.

Provides precise measurements of plate thickness in can manufacturing, featuring a user-friendly design and compatibility with SPC systems for seamless data transfer, ensuring reliable quality control.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.