Click for full sized image

The VLT-ECO Vacuum Leak Tester provides efficient and accurate leak detection for various packaging types, ensuring quality control.

Performs tests on:

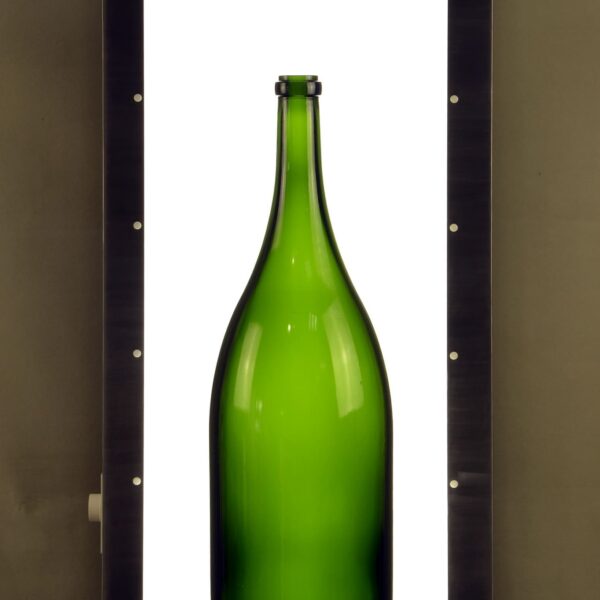

Bottles: Glass or PET, and Preforms

Caps: Aluminum, other metals, plastic

Cans: Aluminum, other

Pots: caps, film, blisters, etc.

VLT-ECO Vacuum Leak Tester for Efficient Leak Detection

The VLT-ECO Vacuum Leak Tester provides precise leak detection for various packaging types, including bottles. This eco-friendly model offers customizable vacuum levels and holding times, making it an essential tool for quality control in multiple industries.

### Advanced Leak Detection

The VLT-ECO can simulate atmospheric pressure changes and conduct altitude variation tests, ensuring comprehensive leak detection.

### User-Friendly Design

With a rugged acrylic construction, it provides a durable, efficient, and affordable testing experience.

### Versatile Applications

This tester is suitable for a wide range of packaging, including glass, plastic, aluminum, PET bottles, metal caps, and more, making it an invaluable tool for various industries.

Specifications:

• Vacuum adjustable down to -999 mb (-0.985 atm; -14.5 psi)

• Customizable dimensions

• Rugged polished transparent PMMA (acrylic) construction

• Easy and safe to use

• Equipped with manometer

• Built with 3-directional valve for controlling air flow

• Accuracy: 2.5% of the measurement

• Built-in vacuum generator (for use with local pressure line)

generates vacuum through venturi effect principle

• Runs with 6 bar (87 psi) pressure network

• Quick and easy verification and calibration

Optional parts:

• Immersion plate (for visual detection of bubbling, which would indicate a leaks)

• High performance pump (vacuum to -999 mb; -0.985 atm; -14.5psi)

The VLT-ECO Vacuum Leak Tester is designed for efficient and accurate leak detection in various packaging types, including bottles, caps, cans, and pots. It is essential for quality control across multiple industries, ensuring the integrity of packaging.

The VLT-ECO can perform tests on a wide range of packaging materials, including glass and PET bottles, aluminum and plastic caps, aluminum cans, and various types of pots, such as those with caps, films, and blisters.

The VLT-ECO simulates atmospheric pressure changes and conducts altitude variation tests, which allows for comprehensive leak detection. It also features customizable vacuum levels and holding times to cater to specific testing requirements.

The VLT-ECO has a vacuum adjustable down to -999 mb (-0.985 atm; -14.5 psi), offers a rugged acrylic construction, and includes a manometer for accurate measurements. It boasts an accuracy of 0.5% of the measurement and features a built-in vacuum generator that operates with a pressure network of 6 bar (87 psi).

Yes, optional accessories include an immersion plate for visual detection of leaks through bubbling and a high-performance pump that can achieve a vacuum of -999 mb (-0.985 atm; -14.5 psi) for enhanced testing capabilities.

Yes, the VLT-ECO is designed with user-friendliness in mind. Its rugged construction and straightforward controls make it easy and safe to operate, allowing for quick verification and calibration of tests.

The VLT-ECO Vacuum Leak Tester provides efficient and accurate leak detection for various packaging types, ensuring quality control.

Performs tests on:

Bottles: Glass or PET, and Preforms

Caps: Aluminum, other metals, plastic

Cans: Aluminum, other

Pots: caps, film, blisters, etc.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.