Click for full sized image

For beer & soft drink

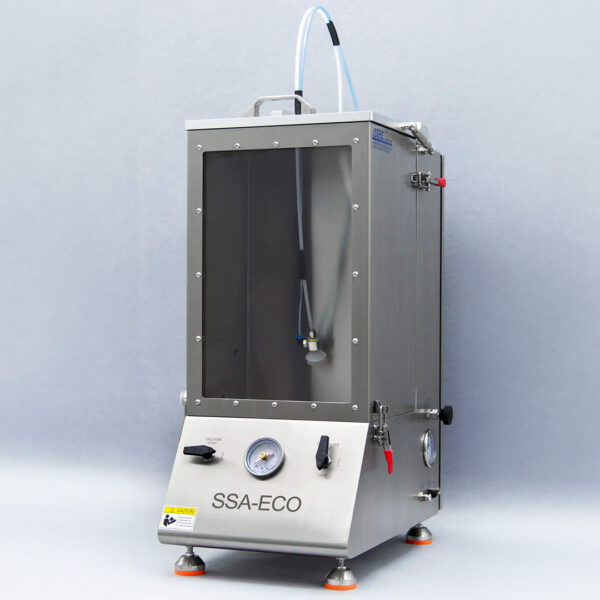

In beer and soft drink industries, reproducible and proper samples from bottles and cans are required for various of quality control processes. The AT2E “BSD-1 Beverage Sampling Device” is designed to be an easy and safe device for this requirement.

AT2E’s BSD-1 Beverage Sampling Device is a manual sampling instrument for bottled and canned products. With its very easy operation, just connect the pressurizing pipe to pressure source, install the beverage onto the base, lift up the handle and the piercing will be performed. Down the piercing needle up to the bottom of sample, then open the tap to raise pressure into sample’s airspace, with pressure effect, liquid will flow into the measuring instrument installed beside.

It’s been widely used in various quality control processes in the beer and beverage industry.

Technical specifications:

The BSD-1 Beverage Sampling Device is designed for manual sampling of bottled and canned beverages, including beer and soft drinks. It ensures reproducible and proper sampling for quality control processes in the beverage industry.

The device operates by connecting a pressurizing pipe to a pressure source, installing the beverage container onto the base, and lifting the handle to pierce the container. Once the piercing needle is submerged in the beverage, opening the tap allows pressure to flow the liquid into the measuring instrument for analysis.

The BSD-1 is compatible with various types of packaging, including glass bottles, plastic bottles, and cans. It is designed for easy adjustments to accommodate different sizes and kinds of packages.

The BSD-1 has an overall size of 5.1″ x 18.3″ (130 x 465 mm) and can sample containers with a height range of 1.6″ to 15″ (40 to 380 mm) and a diameter range of 1.8″ to 4.3″ (45 to 110 mm). It requires a pressure of 0 – 30 psi (0 – 2 bar) and weighs 5 lbs (2 kg).

Yes, the BSD-1 is designed for safe, easy, and rapid sampling, making it user-friendly for operators in the beverage industry.

Yes, the BSD-1 is compatible with other brands of instruments, allowing for versatility in quality control processes.

For beer & soft drink

In beer and soft drink industries, reproducible and proper samples from bottles and cans are required for various of quality control processes. The AT2E “BSD-1 Beverage Sampling Device” is designed to be an easy and safe device for this requirement.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.

Reviews

There are no reviews yet.