Click for full sized image

A precision instrument designed to accurately measure the internal diameter of necked-in cans, offering high-resolution and versatile compatibility for quality control in can manufacturing.

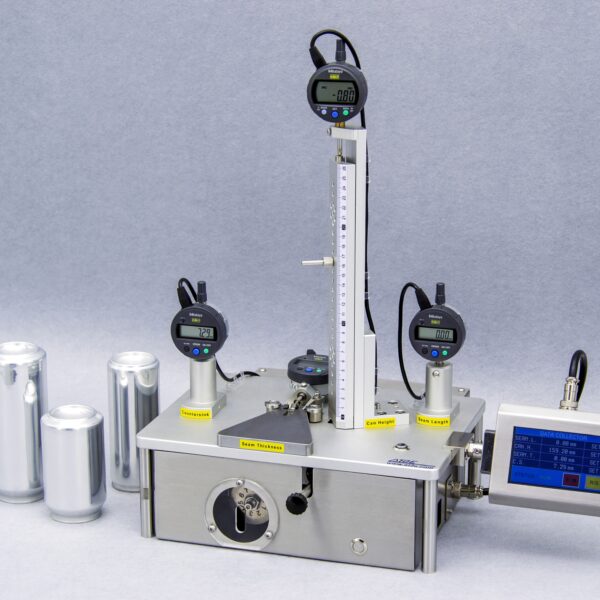

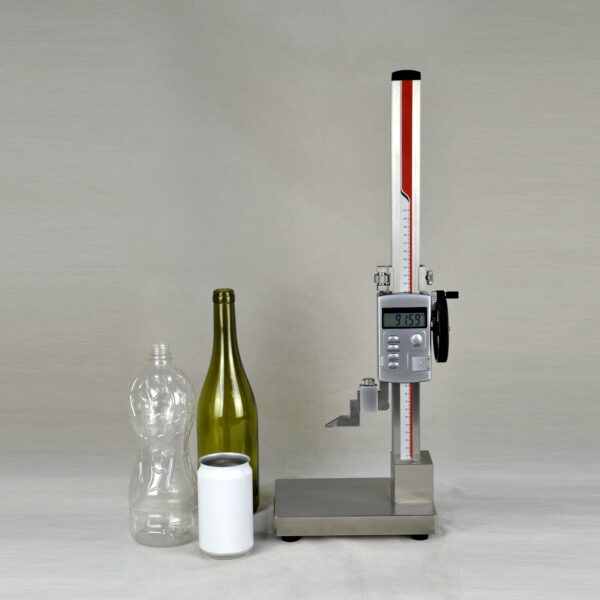

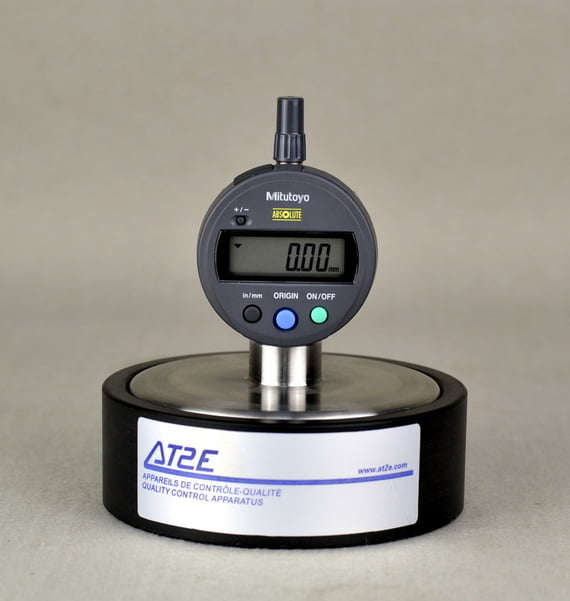

The CIDG-1 Can Internal Diameter Gauge is a precision instrument engineered for accurately measuring the internal diameter of necked-in cans. It plays a crucial role in quality control within can manufacturing, ensuring measurements are consistent and reliable.

High Precision and Accuracy

The CIDG-1 delivers a resolution of 0.01 mm with an accuracy of ±0.01 mm. This high level of precision makes it ideal for detailed inspection and quality assurance processes in can production.

Versatile Compatibility

This gauge is compatible with both 2-piece and 3-piece cans and can be customized to fit various can sizes. Calibration blocks are provided for each specific diameter, ensuring accurate measurements every time.

Durable and User-Friendly Design

Constructed from robust materials, the CIDG-1 is built for longevity. Its compact size—282 mm (11.1 in) in length, 120 mm (4.7 in) in width, and 90 mm (3.5 in) in height—and lightweight design (5 kg/11 lbs) make it easy to handle and seamlessly integrate into existing workflows.

Ensure your can production meets the highest quality standards with the CIDG-1 Can Internal Diameter Gauge, an essential tool for precise internal diameter measurements.

The CIDG-1 Can Internal Diameter Gauge is designed for accurately measuring the internal diameter of necked-in cans. It is an essential tool for quality control in can manufacturing, ensuring that measurements are consistent and reliable.

The CIDG-1 features a resolution of 0.01 mm and an accuracy of ±0.01 mm. It is compatible with both 2-piece and 3-piece cans and comes with calibration blocks for specific diameters. The dimensions of the gauge are 282 mm x 120 mm x 90 mm, and it weighs 5 kg (11 lbs).

Yes, the CIDG-1 is designed with user-friendliness in mind. Its compact size and lightweight construction make it easy to handle, allowing for seamless integration into existing workflows in can manufacturing.

Absolutely! The CIDG-1 can be customized to fit various can sizes, and it includes calibration blocks that ensure accurate measurements for each specific diameter.

The CIDG-1 ensures measurement accuracy through its high precision specifications, featuring a resolution of 0.01 mm and an accuracy of ±0.01 mm. Regular calibration and the use of specific calibration blocks further enhance its reliability for quality assurance processes.

The CIDG-1 is constructed from robust materials designed for durability, ensuring that it withstands the rigors of industrial use while maintaining its precision and accuracy over time.

A precision instrument designed to accurately measure the internal diameter of necked-in cans, offering high-resolution and versatile compatibility for quality control in can manufacturing.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.