Click for full sized image

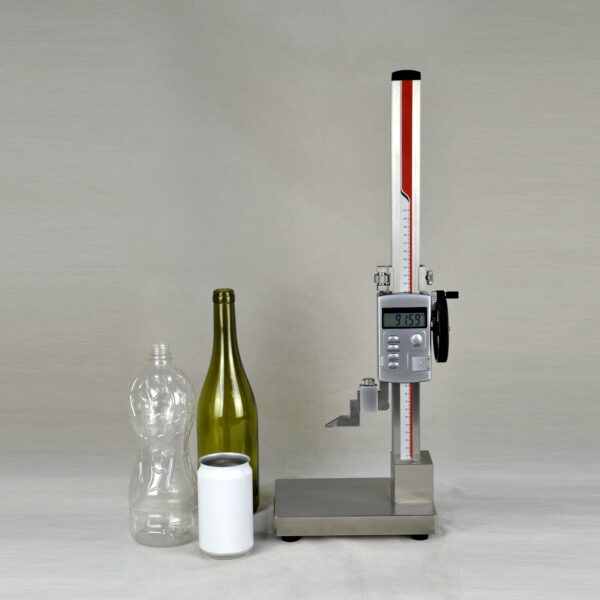

A durable and versatile device designed to accurately test the seal integrity of bottles, cans, and preforms, ensuring product quality and safety with its explosion-resistant stainless steel construction and adaptable needle options.

The SSA-ECO Bottle Seal Tester provides accurate testing of seal performance for bottles and cans, ensuring product integrity. Its design allows for quick and easy setup, accommodating various testing configurations.

The SSA-ECO can measure up to 16 bar (232 psi) and displays results on an analog gauge. It is versatile, suitable for testing bottles, cans, and preforms, making it an essential tool in quality control processes.

Constructed from stainless steel, the SSA-ECO is explosion-resistant and ensures safe operation. It can be used with the patented needle or standard screwed needles, making it adaptable to different testing needs.

Optional accessories such as a cap holder, cutting tool, and bottle support expand the tester’s capabilities, making it a comprehensive solution for seal testing.

The SSA-ECO Bottle Seal Tester is a crucial tool for maintaining high standards in seal integrity, providing reliable and efficient leak detection.

The SSA-ECO Bottle Seal Tester is designed to accurately test the seal integrity of bottles, cans, and preforms. It ensures product quality and safety by detecting leaks, making it an essential tool for quality control in various industries.

The SSA-ECO features a durable construction made from explosion-resistant stainless steel, ensuring safe operation and longevity in various testing environments.

The SSA-ECO can measure pressure up to 16 bar (232 psi) with a resolution of 0.5 bar (7.2 psi), making it suitable for a variety of seal testing applications.

Yes, the SSA-ECO offers several optional accessories, including a cutting tool for cap testing, a cap holder, bottle support, and standard screwed needles. Additionally, there is an SSA-ECO-3 model available that allows for three simultaneous test positions.

The SSA-ECO is designed with safety in mind, featuring an explosion-resistant stainless steel construction and an adjustable pressure regulator to manage the testing pressure effectively.

Yes, the SSA-ECO is compatible with AT2E’s patented special needle as well as standard screwed needles, allowing for adaptability in various testing scenarios.

A durable and versatile device designed to accurately test the seal integrity of bottles, cans, and preforms, ensuring product quality and safety with its explosion-resistant stainless steel construction and adaptable needle options.

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

We develop and sell a wide range of packaging test machines for various industries.