Quality Control Equipment for Packaging

AT2E makes packaging and bottle test equipment for the Beverage, Food, Pharmaceutical, Cosmetics

Chemical and Laboratory industries.

Torque Testers

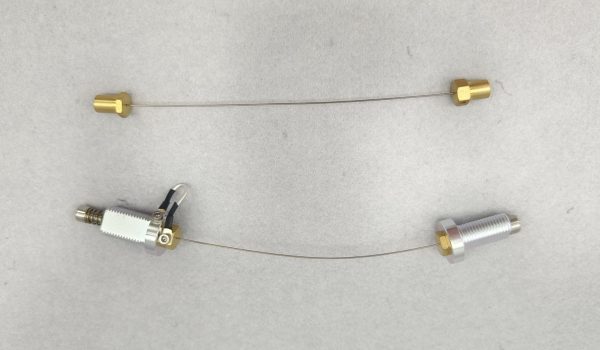

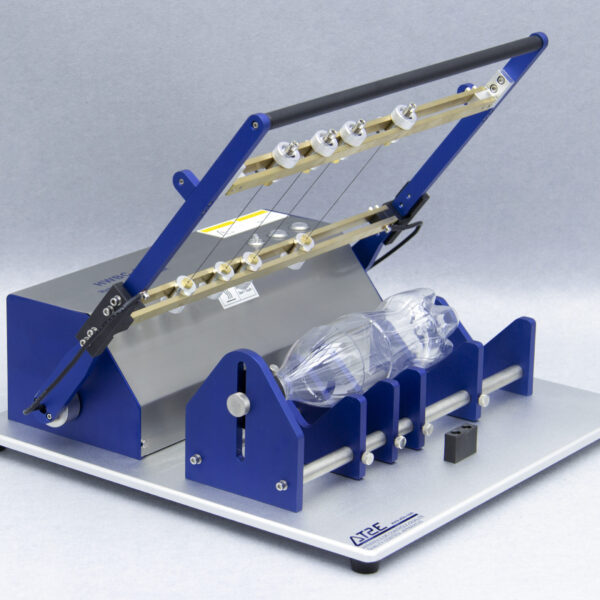

HOT WIRE BOTTLE CUTTERs/SECTION CUTTERS

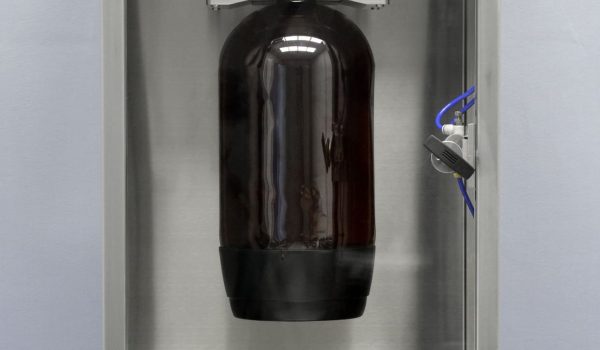

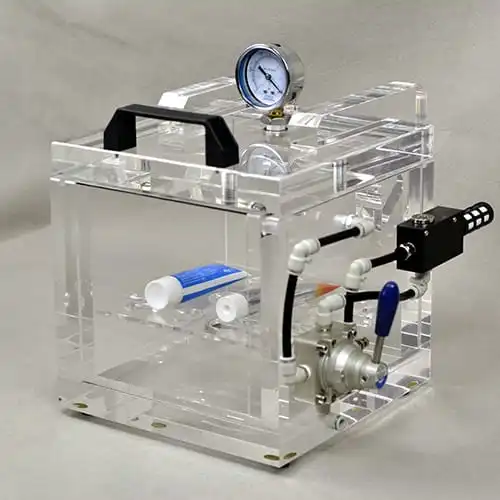

Vacuum Leak Testers / Vacuum Chambers

Secure seal testers

Burst Testers

Stress Crack Testers

CO₂ TESTERs

Pressure & Vacuum Gauges

Aphrometers

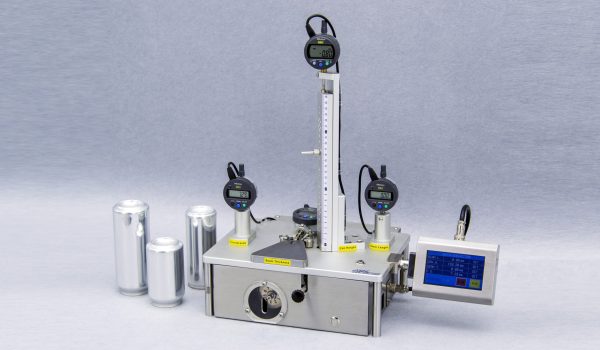

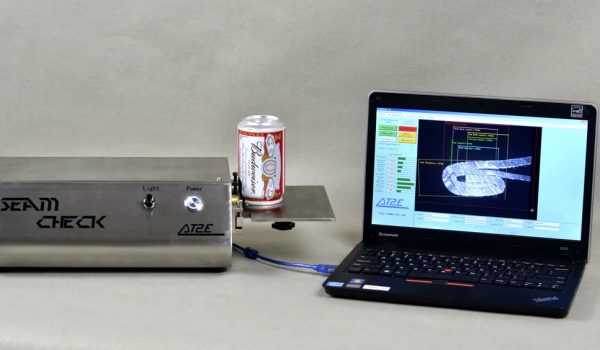

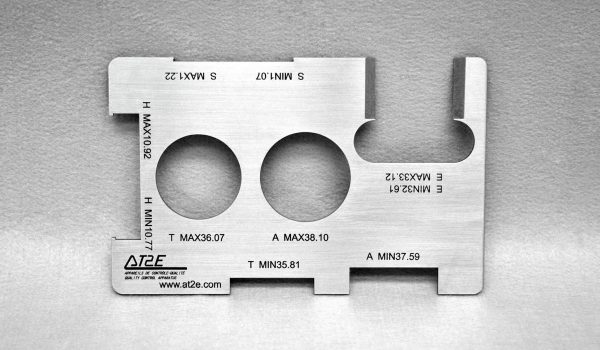

Can & Aerosol Seam mEASURING DEVICES

Dynamometers, traction & Force Gauges

Impact Testers

sanitary can testing devices

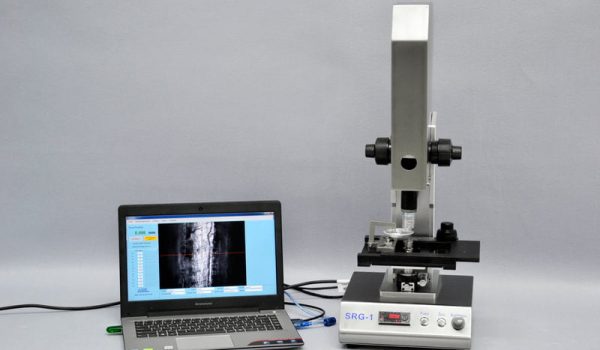

Polariscopes / POLARIZATION LIGHT

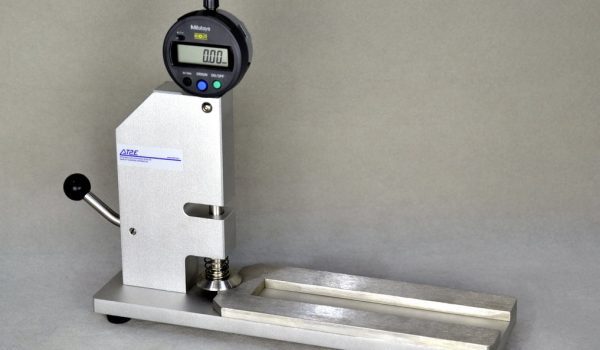

Dimensional / Verticality / Roundnesss gauges

FILLERS AND CAPPERS

Browse 120+ test machines

-

Torque Testers (10)

-

Stress-Application (3)

-

Pressure and Vacuum Gauges (9)

-

PET Section Weight (8)

-

PET Preform (12)

-

PET Plastic Bottles (45)

-

Leak Testers (9)

-

Glass Bottles (50)

-

Force / Compression (16)

-

Enamel Integrity (1)

-

Dimensional (35)

-

Crown Cap (13)

-

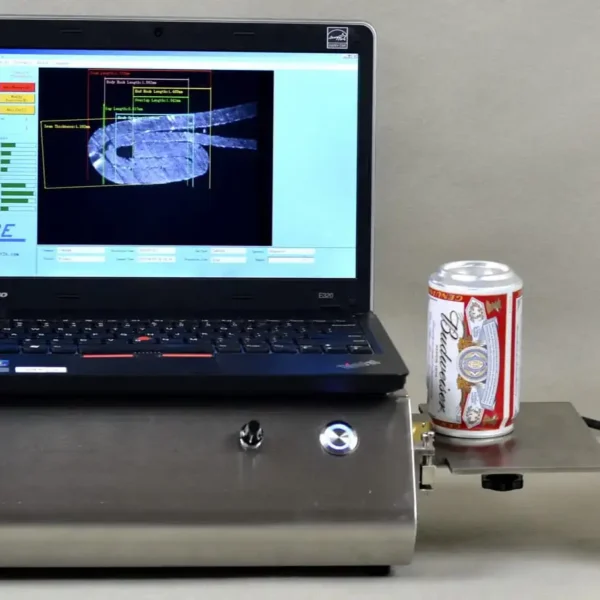

Can-Seaming (21)

-

Burst testers (7)

-

Automated Integrated Tester (2)

-

Aphrometer (4)

Featured Products

Sort by sample category

Looking for a product for specific needs?

Contact us now

We can design and build custom QA machines to fit your unique sample

average response time less than 30 minutes

Trusted By

About us

We have developed over 200 different packaging test machines since our founding in 1989.

Our in-house team of engineers carefully designs and manufactures each instrument to solve a specific quality control problem.

If you do not find a solution that fits your needs, please contact us.

We can also design and build custom QA machines to fit your unique requirements.

Our products

We develop and sell a wide range of packaging test machines for various industries.

- Torque testing machine for bottle caps

- Leak detection testing through pressurization and vacuums

- Force / compression / dynamometer measurements

- CO2 / pressure / vacuum gauges

- Stress testing equipment

- Dimensional measurements (height, length, thickness, perpendicularity, circumference, diameter)

- Crown cap measurements

- Glass and plastic bottle burst pressure testing

- Plastic bottle cutter machine for PET section weight analysis

- Internal enamel integrity testing

- Aluminum can quality assurance testing